Timing-Belt Kit allows on-site installation.

Press Release Summary:

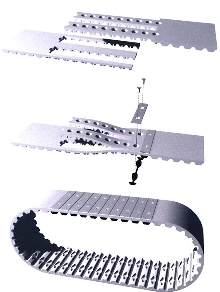

ATN® mechanical connection system facilitates rapid belt assembly and disassembly directly at drive set-up. Finger spliced ends have clamping hardware consisting of polyamide inserts, steel plates, and screws. Allowable tensile load for ATN 10 and ATN 12.7 tooth pitch polyurethane belts is up to 337.2 lbs. Kit is available for 50 mm and 100 mm wide belts.

Original Press Release:

Quick And Easy Timing Belt Installation On-Site

ATN® - Connecting Kit for Field Assembly BRECOflex CO., L.L.C., the pioneer and world leader in the polyurethane timing belt industry introduces the new and unique ATN® connection technology. This mechanical connection system is designed for rapid belt assembly and disassembly in the field to be installed directly at the drive set-up. The finger spliced ends of the timing belt are prepared at the factory for field installation with special clamping hardware, which consists of high strength polyamide inserts, high-grade steel plates, and the requisite screws. This connection technology also allows ATN convertible profiles to be attached even in the joined area. The allowable tensile load (Fzul. in N) for ATN 10 and ATN 12.7 tooth pitch polyurethane timing belts is up to 1500 N = 337.2 lbs. The connecting kit is available for ATN timing belts 50 mm and 100 mm wide.