Thread Grinder features robot load/unload system.

Press Release Summary:

Equipped with linear motors and ways, Model GS:TE-LM features 180° power helix, Fanuc control programmed with customer parts, acoustic touch dressing, automatically generated wheel forms, and mineral-filled cast polymer base. Auto load system consists of infeed conveyor, robot with dual grippers, and exit conveyor. When new part information is entered into menu during changeover, robot is automatically reprogrammed for part being presented.

Original Press Release:

Drake to Show New Linear Motor Thread Grinder with Robot Loader At IMTS

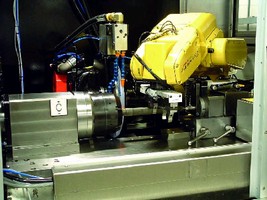

WARREN, OHIO- At IMTS, Drake Manufacturing will show off its new GS:TE-LM thread grinder fitted with a sophisticated robot load/unload system that provides maximum throughput for high volume production of ground threads.

The GS:TE-LM is a full helix thread grinder equipped with a host of advanced machine design and grinding technologies including a 180° power helix, linear motors and ways, latest Fanuc control programmed with customer parts, acoustic touch dressing, automatically generated wheel forms and a mineral filled cast polymer base.

It's the ideal grinder for taps, multi-start worms, electronic steering components, fast lead ball screws, feed and bone screws, gear boxes, transmissions and speed reducers.

The auto load system consists of an infeed conveyor, robot with dual grippers, and an exit conveyor. The infeed conveyor and grippers allow fast changeovers on families of parts. During the cycle, the robot loader lifts a new blank off the infeed conveyor and deposits a finished part on the exit conveyor at the same time.

Changeovers are accomplished in minutes because robot cycles are coordinated with Drake's PartSmart(TM) programs. The robot load system is pre-programmed to automatically respond to part dimension changes.

When new part information is entered into the menu during changeover, the robot is automatically reprogrammed for the part being presented.

The system can conform to customer restocking intervals and can be easily integrated into manufacturing cells. The entire grinding and load/unload sequence is programmed into the control by Drake.

Changes in part lengths are handled by adjusting the conveyor width and headstock position.

Drake is exhibiting in Booth B-7407 at IMTS.

Drake Manufacturing designs, builds and services state-of-the-art precision CNC grinding, rack milling and gear hobbing machines that help maximize productivity, improve quality and reduce production costs for a wide variety of demanding applications.