Position Sensors / Detectors / Transducers

Test Kit verifies sensor function after installation.

Press Release Summary:

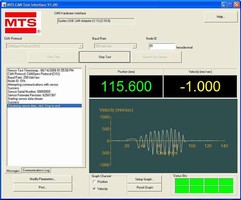

Portable in design, M-Series CAN Test kit allows cylinder manufacturers to verify functionality of CAN protocol versions of M-series linear position sensors once installed in cylinders. It includes GUI and AC/DC converter that provides power directly to sensor, isolating it from rest of vehicle. Kit also includes test cable with M12 plug, which mates with M12 Integrated Connector System, and cable allowing customization to other connector systems.

Original Press Release:

MTS' Test Kit Eases Verification of Sensor Functionality

CARY, NC - (October 16, 2008) - MTS Systems Corp., Sensors Division has developed a portable test kit for the CAN protocol versions of its off-highway M-series linear position sensors to assist cylinder manufacturers and equipment OEMs in the off-highway market to verify functionality of the sensors after they are installed. During installation into hydraulic cylinders these sensors may be exposed to potentially damaging conditions so it is important to be able to test them before shipping the cylinder assembly to the OEM equipment manufacturer.

The M-Series CAN Test kit will allow cylinder manufacturers to verify the functionality of the sensors once they are installed in cylinders, prior to the cylinders being shipped to the cylinder manufacturer's customers. For OEMs, it will help determine if a faulty read on a controller is caused by a malfunctioning sensor or by other factors such as the controller's software.

"We wanted to provide our customers with an efficient and cost-effective solution to troubleshoot problems on equipment both at the factory or when problems arise in the field," said Brian Cox, technical marketing manager for mobile hydraulic sensors at MTS.

"Testing equipment with the CAN outputs can be especially difficult but with MTS' test kit, immediate on-site evaluation of the sensor can quickly and easily identify problems without loss in time and productivity."

The test kit includes an easy to use GUI (Graphical User Interface) and an AC-to-DC converter that provides power directly to the sensor thus isolating the sensor from the rest of the vehicle. This is useful because the sensor's functionality can be verified independently from the rest of the vehicle. Quickly identifying the sensor's functionality can save time and expense that result when a fully functioning sensor is misidentified as faulty.

The M-Series CAN Test Interface can be quickly attached to the sensor under test by connecting one of two cable assemblies with the CAN to a USB module connected to a computer running the M-Series CAN Test Interface. The first test cable comes with an M12 plug, which mates with MTS' M12 Integrated Connector System.

The M-Series CAN Test Interface reports the functionality of the sensor but is also able to report error-checking and error bytes from the sensor itself, and it can provide printed reports. The software also allows customers to change the node ID or baud rate of a sensor directly through the CAN lines. Also included in this kit is a cable that allows the test interface to be customized to other connector systems.

MTS' durable, non-contact Temposonics® off-highway sensors provide reliable operation under the most difficult conditions including high levels of shock and vibration, adverse climatic conditions and electrical magnetic interference. This makes them ideal solutions for many industries including agriculture, construction, mining, material handling, waste handling vehicles, military and other off-highway applications.

For more information on the M-Series CAN Test Kit, please contact: Brian Cox, MTS Sensors Division, 3001 Sheldon Drive, Cary, NC 27513; call (919) 677-0100; email brian.cox@mts.com; or visit www.mtssensors.com.

MTS Systems Corporation is the world leader in magnetostrictive linear position and liquid-level sensor technology. MTS Systems Corporation is a global operation, with facilities in the U.S., Germany and Japan. In the U.S., the MTS Sensors Division has an ISO 9001 facility manufacturing rugged and reliable liquid-level and linear position sensors based on patented MTS Temposonics® technology. With a strong commitment to research and development, product quality and customer service, the Sensors Division is constantly seeking ways to bring the highest value to customers.