TDM/TLM Software supports Industry 4.0 development.

Press Release Summary:

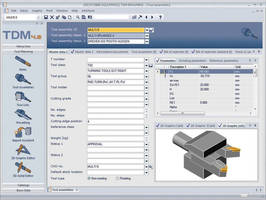

Advancing Tool Data Management (TDM) towards Tool Lifecycle Management (TLM), TDM v4.8 offers multi-tool support in TDM Base Module, data import from MachiningCloud, wireless connection for barcode scanners in TDM Tool Crib module, and at-a-glance CAM data for operator. Functionality accelerates and facilitates generation of solid models for tool assemblies, and menu tab in tool assembly management shows CAM programmer required tool parameters. Solid models are compatible with CAM system.

Original Press Release:

TDM Systems Announces TDM Release 4.8

As part of the company’s ongoing development for Industry 4.0, TDM Release 4.8 helps form the sophisticated basis for Tool Lifecycle Management

Schaumburg, ILÂ – TDM Systems, a software manufacturer, process consultant and leader in electronic management of tools and production equipment has announced the release of its latest version 4.8 that will provide added optimization to continue to lead the way from Tool Data toward Tool Lifecycle Management (TLM).

"On the shopfloor, Tool Lifecycle Management is the key element of Industry 4.0," explains Peter Schneck, Managing Director of TDM Systems. "Our software sits at the interface between planning and real world production."

The most important innovations to this release are; multi-tool support in TDM Base Module; data import from MachiningCloud; wireless connection for barcode scanners in TDM Tool Crib module (LGM); at-a-glance CAM data for the operator; and the ability to generate solid models for tool assemblies faster and easier.

Multi-functional tools have multiple cutting edges for different machining purposes. The new TDM version now combines more tool assembly data records with the same bill of materials in a so called multi-tool data record. When searching for tools, it is now possible for users to see the search criteria corresponding to partial data records of a multi-tool displayed as well as the multi-tool data record.

For the internet-based tool database, MachiningCloud TDM V4.8 (hotfix 1) provides a mapping for the import of tool data. This automatically assigns the ISO tool parameters from MachiningCloud to the TDM class/group structure parameters.

In Release 4.8, the interface to the new CASIO scanner DT-200 has been extended so that it can be connected to the system wirelessly. All issuing processes are made without caching and offline transmissions, via a base station, are transmitted quickly to the system.

The new menu tab in the tool assembly management shows the CAM programmer the required tool parameters. Depending on the CAM tool class, the programmer sees the associated TDM tool class with the relative graphic parameters and TDM parameter description.

With version 4.8, users receive even faster and easier solid models, which are compatible to work with the CAM system. Available since V4.6, the Revolve Generator for generating 3D-models from contours of rotationally symmetric items now works also at the tool assembly level. TDM Release 4.8 will be available November 2015.

For over 25 years, TDM Systems has been the leading provider of tool data management in creating and editing tool data and graphics, integrating tool expertise and 3D graphics into the CAM engineering and organizing the complete tool cycle at the shop floor level are the three core competencies of TDM Systems and the pillars of the TLM strategy. As a competence center within the Sandvik Group, TDM Systems draws on the experience of various toolmakers in developing its software products.