Swage Mount PCB Pins are made from brass alloys.

Press Release Summary:

Designed to be mechanically fastened to board or panel and plugged into sockets or soldered into mating boards in board stacking, Swage Mount PCB Pins are available in six models with various diameters and lengths. Long pin lengths can overcome height of taller board components such as large capacitors, transformers, power supplies and potentiometers. Units come with matte tin over nickel plating and are annealed to prevent cracking in swaging operation.

Original Press Release:

Swage Mount PCB Pins for Interconnect Applications

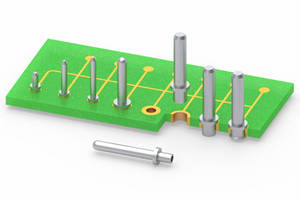

Mill-Max is adding to its diverse mix of swage mount PCB pins with six new offerings designed for interconnect applications. These swage mount terminals are designed to be mechanically fastened to a board or panel and plugged into sockets or soldered into mating boards in board stacking and other interconnect configurations.

Swage pins are often thought of as wire-to-board soldering terminals and test points or as hardware such as PCB standoffs, but they are also an excellent choice for board-to-board interconnects. They are cost effective due to their simple design, don’t require the more precise PCB hole specifications associated with most press-fit pins and can be processed in volume with semi-automatic or automatic equipment. Swage assembly is a method of mechanically fastening pin terminals to a circuit board, similar in style to riveting. After the pins are swaged, they are soldered, providing a robust mechanical and reliable electrical connection.

The swage pins featured here are offered in various diameters and lengths to suit a wide variety of interconnect applications. They are useful when space is limited, near the edge of a board for example, where a connector with its housing is not an option. The swaged pin takes up relatively little space and is secure without the need of an insulator. The longer pins are perfect for overcoming the height of taller board components (large capacitors, transformers, power supplies, potentiometers) to connect to a daughter card or other module, while the low profile 4658-0 maybe used on boards which are primarily SMT, to keep the overall stacked board assembly height to a minimum.

All the pins are high speed precision turned from brass alloys and annealed to prevent cracking during the swaging operation. The standard plating for these pins is matte tin over nickel with other plating options available upon request.

Part Number Pin Diameter(in) Pin Length Suggested Mounting Maximum Board

for Mating (in) Hole Diameter (in) or Panel thickness (in)

4658-0-00-80-00-00-08-0 .040 .094 .043 .062

4275-0-00-80-00-00-08-0 .040 .235 .043 .075

9103-0-00-80-00-00-08-0 .040 .300 .043 .031

4639-0-00-80-00-00-08-0 .062 .432 .065 .062

4717-0-00-80-00-00-08-0 .062 .332 .065 .062

9242-0-00-80-00-00-08-0 .062 .375 .094 .075

For more information, use the links to the right for additional product details, to find related products, or contact Mill-Max Technical Services (https://www.mill-max.com/technical_assistance_form/) for additional questions.

For over 45 years, Mill-Max has been manufacturing and designing high reliability precision-machined interconnect components, and is a recognized global leader in both industry standard and application specific interconnects. Our US based manufacturing is housed entirely in one location ensuring MAXIMUM reliability, service, and convenience.

Contact:

Mill-Max Mfg. Corp.,

190 Pine Hollow Rd.,

Oyster Bay, NY 11771. USA

Call: 516.922.6000