Stacked LED Assembly retrofits to current set-ups.

Press Release Summary:

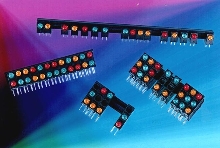

Multi-stack LED assembly allows custom configuration of LEDs stacked 1, 2, and 3 high, with spacing up to 6 in. wide, without special tooling. Operators can install from 6 to 36 LEDs at once in complex configurations. All LEDs have proper viewing angles, correct sequencing and polarity, and consistent color matching. Assembly also provides resistance to shock and vibration. It is made from UL 94V-O rated Valox 420 plastic.

Original Press Release:

Stacked LEDs Go High And Wide To Minimize Labor and Boost Quality

Engineers at Wilbrecht Electronics' have designed a multi-stack LED assembly that allows custom configuration of LEDs stacked 1, 2, and 3 high with custom spacing going up to 6" wide without paying for any special tooling. The Wilbrecht multi-stack assembly cuts installation to a fraction of the time. It allows the operator to install from 6 to 36 LEDs all at once in complex configurations. In one simple operation, all LEDs have the proper viewing angle, correct sequencing and polarity, and consistent color matching. Along with enhanced reliability, the assemblies provide improved resistance to shock and vibration.

The assemblies are very effective in cutting labor and boosting quality in high density areas. For new applications in industrial, data communications, aerospace, military, and telecommunications, they allow designers to conserve valuable board space and increase durability. For existing applications, the assemblies are easily retrofit to the current set-ups to readily take full advantage of the significant labor savings and improved product reliability. The multi-stack assemblies are made from UL 94V-O rated Valox 420 plastic for conventional wave soldering.