Stacked Ceramic Disc Capacitors are RoHS compliant.

Press Release Summary:

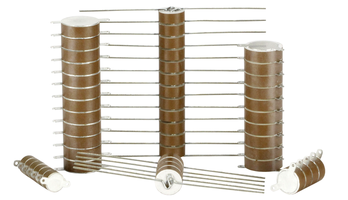

Available in ST1, ST2 and ST3 series models, Stacked Ceramic Disc Capacitors are suitable for electrostatic paint spraying and portable x-ray systems applications. Offering capacitance range from 130 to 1,000 pF per disc with voltage range of 6,000 to 12,000 volts, ST1 series features wire leads between each stage whereas ST2 and ST3 comes with solder tabs with 180° and 140° separation respectively. Units are made from class II ceramic dielectric materials.

Original Press Release:

ST1, ST2, & ST3 Series – High Voltage Ceramic Capacitor Stacks

Dean Technology, Inc., today announced the introduction of its new line of high voltage ceramic capacitor stacks the ST1, ST2, and ST3 series. These are a new line of stacked ceramic disc capacitors, with three different terminal types that range from 6,000 to 12,000 volts and 130 to 1,000 picofarads per disc. They are made from Class II ceramic dielectric materials, with noble metal electrodes, and are all RoHS compliant.

Available as standard parts with four to twelve stages, capacitor stacks are ideal for use in constructing compact half and full wave multipliers for countless applications including electrostatic paint spraying and portable x-ray systems. The ST1 series has wire leads between each stage, while the ST2 and ST3 parts have solder tabs with 180-degree and 140-degree separation respectively. The flexibility and space efficiency of this product line, when paired with Dean Technology’s lines of HVCA axial lead and surface mount high voltage diodes offer an impressive design option for new multiplier designs.

“We’re using some impressive advanced soldering technology and automation to produce our new capacitor stacks,” said Lynn Roszel, Engineering Manager for Dean Technology, Inc. “This is allowing us to produce a much higher quality part, here in the US, and gives us a cost advantage against other companies’ offerings. It’s very exciting how by using these techniques we can produce prototypes with extraordinarily short lead times.”

A wide range of voltages, capacitance values, number of stages, and terminal configurations are available immediately as standard products in the ST1, ST2, and ST3 series. Dean Technology can also offer custom versions of capacitor stacks with virtually any other ceramic capacitor disc we produce. Custom terminal types are simple to achieve due to the flexible and advanced soldering method employed, and lead times for new versions or engineering prototypes are a matter of weeks, not months like the competition. Full product details can be found on the company’s website, and are available directly from Dean Technology or through any approved sales channel.

About Dean Technology, Inc.

Dean Technology, Inc. (www.deantechnology.com) specializes in the manufacture, distribution and support of high voltage components, assemblies and power supplies. Its three main product lines include HV Component Associates (HVCA), CKE, and High Voltage Power Solutions (HVPSI). The HVCA line of products centers on high voltage diodes, rectifiers, bridge rectifiers, ceramic disk capacitors, and custom assemblies for specific applications. CKE products are a leading line of high voltage and high power silicon rectifiers, MOVs, selenium suppressors, silicon carbide varistors, as well as custom assemblies. The HVPSI product line includes high voltage power supplies, multipliers and test equipment. Dean Technology’s full family of products provides complete coverage of high voltage and high current solutions for any application. For sales and technical information Dean Technology can be reached at +1.972.248.7691.

Press Contact:

Griffin Caruolo

P.O. BOX 700968

DALLAS, TX 75370

972.248.7691