Software recommends optimized cutting speed and feed.

Press Release Summary:

KnowledgeBase(TM), featured in ESPIRIT 2003, utilizes work piece materials, machining operations, cutting depths, and cutter materials to select best-known spindle speed and feedrate for given cutting situation. Working within KnowledgeBase(TM), CUTDATA offers over 100,000 recommended cutting speeds and feederates for 22 machining operations, 12 cutter materials, and over 3,700 work piece materials. Shops can extend list to include favorite cutter and workpiece materials.

Original Press Release:

ESPRIT CAM 2003 Offers TechSolves's CUTDATA for Cutting Speeds and Feeds

Latest Product Offers New KnowledgeBase(TM) with Optional CUTDATA Recommendations for Optimizing Speed and Feedrate Values

Camarillo, CA- DP Technology announces the availability of TechSolve's CUTDATA, the industry's foremost machining database, within the new KnowledgeBase(TM) featured in ESPRIT 2003. The new ESPRIT KnowledgeBase(TM) utilizes work piece materials, machining operations, cutting depths, and cutter materials to select the best-known spindle speed and feedrate for the given cutting situation. Working within this ESPRIT KnowledgeBase(TM), CUTDATA offers over 100,000 recommended cutting speeds and feederates for 22 machining operations, 12 different cutter materials and over 3,700 different work piece materials. In addition, shops can easily extend this list to include their favorite cutter and workpiece materials, providing them with the assurance of accurate speed and feedrate recommendations no matter what material they choose.

ESPRIT KnowledgBase(TM) Recommends Optimized Cutting Speed and Feed Values

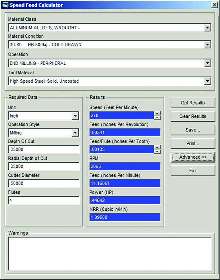

The ESPRIT KnowledgeBase(TM) determines the optimum spindle speed and cutting feedrate, guiding users through the process by means of dialogue boxes which enable them to easily select the Material Class and Condition, the Type of Cut, and Tool Material from ESPRIT's drop-down menus. If the desired cutter and part material is not included in ESPRIT's extensive database, users can enter customized settings.

For example, a shop machining an electronic housing can select "ALLOY STEELS, CAST- Low Carbon" as the Class and "250-300HB - QUENCHED AND TEMPERED" as the Condition. Part Material settings only need be entered once: ESPRIT maintains these settings while allowing the user to adjust tooling and operations as needed. The shop selects "Carbide" as the Tool Material and "End Milling- Peripheral" for the Type of Cut, producing default speed and feedrate values. Once the user enters in specific Cut Depth and Cut Depth Radial (step over) values, ESPRIT updates the speed and feedrate immediately, recommending the optimum settings for machining the part.

Available with the latest version of ESPRIT, 2003

The culmination of over twenty years of research and development, ESPRIT 2003 is DP's most significant release to date and features four product lines - SolidMill, SolidTurn, SolidMillTurn, and SolidWire - each specifically designed to meet the demands of the production machining environment. ESPRIT 2003 incorporates a collection of new machining cycles for milling and turning including 3D Re-machining, 2D Rest-Machining and Advanced Pocket Finishing, plus 100's of additional advancements for its SolidMill, SolidTurn, and SolidWire products.

About DP Technology and ESPRIT

DP Technology is a CAM (Computer Aided Manufacturing) software market leader with a mission to provide CNC programmers with the most powerful CAM software ever. The company's vision of technology's potential and passion for excellence is captured in its flagship product ESPRIT.

DP Technology maintains its worldwide headquarters and product development teams in Camarillo, California along with sales and support operations in Europe, Asia, and North and South America. For additional information about DP Technology and ESPRIT, call +1-805-388-6000, email DP at esprit@dptechnology.com, or visit them on the World Wide Web at www.dptechnology.com.