Sludge Removal System suits paint spray booth applications.

Share:

Press Release Summary:

Maintenance-free Mass Flow(TM) System removes spent residue, paint, or pigment and recycles 60-80% of water back into system, keeping it clean for prolonged periods without sludge buildup. It provides close, constant monitoring and control of water level in recovery tank. With optimum water level and proper chemicals for coagulation, spent residue or paint flotation is maintained and water flow in tank is continuous. Tank can not be blocked with sunken sludge.

Original Press Release:

KMI Systems, Inc Announces the Patent for its Proven Mass Flow(TM) Sludge Removal System... Savings as Great as $100,000 Per Year

CRYSTAL LAKE, ILLINOIS U.S.A. - KMI SYSTEMS, Inc is pleased to announce the newly patented (Pat No. US 6,682,654 Bl) Mass Flow(TM) Sludge Removal System for use in water washed paint spray booth applications and other sludge producing environments.

The maintenance-free system and method remove spent residue, paint or pigment, recycle 60 to 80% of the water back into the system, keeping the system entirely clean for prolonged periods without sludge buildup even during downtime.

This Sludge Removal System and method provide close, constant monitoring and excellent control of the water level in the recovery tank. With an optimum water level and proper chemicals for coagulation, the spent residue or paint flotation is maintained and the water flow in the tank is continuous. The tank cannot be blocked with sunken sludge. This fact has proven to be a key factor in the success of the system.

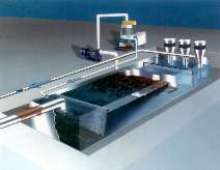

The main components of this patented system include the sludge removal tank, centrifuge, agitation equipment and controls. An optional scavenger pump can be added to remove large chunks of residue or paint sludge prior to entering the chemical tank. Tank agitation through proper pumping action helps increase centrifugal efficiency, the next phase of the system.

By successful removal of approximately 60 to 80% of the water content, considerable weight is eliminated from the residue or paint sludge which results in significant waste removal weight and volume savings. In addition, the system saves earth's valuable water resource along with the costs of its processing and disposal.

Kevin Coursin, President of KMI Systems, Inc., states, "Installations have found this patented system successful in correcting traditional inadequacies in sludge removal. The engineered system monitors and controls water levels effectively to provide proper float. A centrifuge removes water from the solids to leave a much lighter cake for disposal. Chemicals and water are recycled. The system is maintenance-free, keeping itself clean. A central processor controls and monitors all operations. It's really a solid answer offering considerable cost savings."

Like many manufacturers, Mack Trucks Inc. (Macungie, PA) faced a problem when production volumes increased. Their paint booth system was originally designed for painting approximately 50 chassis per day, but increased demand requires output to be 76 chassis per day. The equipment used to recover paint sludge from their paint booths no longer kept up with production volume. Mack chose KMI's patented 'Mass Flow' System. It has proven to dramatically reduce costs in labor, water consumption and chemical use. Design and installation for Mack was completed in less than 3 months. Once installed, it only took a few hours to get the system up and running. After more than 2 months on-line, the 'Mass Flow' system has eliminated all traces of sediment in the water pits.This has exceeded Mack's ambitious goals of reducing the pit cleaning task to once every 6 months. With this 'Mass Flow' system, Mack expects to clean annually, and only if needed.

In addition to labor savings because of reduced cleanup, Mack has also saved money on chemicals. "The centrifuge is so efficient, we don't need a lot of extra chemicals to coagulate the residue or paint. And, this system virtually eliminates clogging."

An initial cost analysis at Mack has shown savings of nearly $ 100.000 per year,

A brochure and Q&A is available from KMI Systems, Inc. at no cost or can be viewed online at http://www.kmisystemsinc.com/sludgeQA.pdf.