Floor, Lift Truck and Conveyor Scales

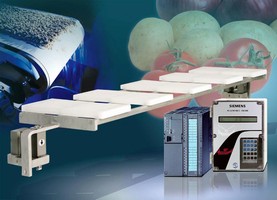

Slider-Bed Belt Scale measures light-to-medium-duty loads.

Press Release Summary:

Suitable for flat belt conveyors transporting dry products as well Intralox style belts conveying wet products in food/beverages, pharmaceuticals, and tobacco industry, Milltronics Weighdeck 600 features corrosion resistant components that are virtually maintenance-free. Belt support bed is made of Ultra High Molecular Weight polyethelene. IP67 protected WD600 is available with nickel-plated alloy steel or hermetically sealed SS load cells of different sizes.

Original Press Release:

New Slider-Bed Belt Scale for Light-to-Medium-Duty Loads

ATLANTA, June 3, 2008 - Siemens Energy & Automation, Inc. today announced the introduction of a new slider-bed belt scale that measures light-to-medium-duty loads. The Milltronics Weighdeck 600, with IP67 degree of protection, is suitable for flat belt conveyors transporting dry products as well for Intralox style belts conveying wet products. As a system, including an integrator and a speed sensor, daily production totals can be tallied. The areas of application range from food and beverages through pharmaceuticals to the tobacco industry.

The Milltronics WD600 belt scale offers many features including easy installation and robust, corrosion resistant components that are virtually maintenance-free. It is especially suitable for aggressive environments and the hygienic processing of foodstuffs. The belt support bed is made of Ultra High Molecular Weight (UHMW) polyethelene and the scale is either available with nickel-plated alloy steel or hermetically sealed stainless steel load cells. Fitted with load cells of different size, the WD600 is suitable for universal use on flat slider belt conveyors from very low to medium loads.

The WD 600 weighbridge, together with a speed sensor and the BW100 or BW500 integrator form an advanced weighing system. This system can be used, for example, to determine the instantaneous belt load and speed, or to calculate the daily production total with a totalization accuracy of 0.5 -1.0 percent. Accuracy is maintained even with severe off-center belt loading due to electronic load cell balancing. When used with the PID controller built into the BW500 and a variable frequency drive, the WD600 can also be used to control feed rates by varying the belt speed accordingly to demand.

More information on the Milltronics WD600 is available at: http://www.siemens.com/wd600

About Siemens

Siemens Energy & Automation, Inc. is one of Siemens' operating companies in the U.S. Headquartered in the Atlanta suburb of Alpharetta, Ga., Siemens Energy & Automation, Inc. manufactures and markets one of the world's broadest ranges of electrical and electronic products, systems and services to industrial and construction market customers. Its technologies range from circuit protection and energy management systems to process control, industrial software and totally integrated automation solutions. The company also has expertise in systems integration, technical services and turnkey industrial systems. For more information: www.sea.siemens.com.

Siemens AG (NYSE: SI) is a global powerhouse in electronics and electrical engineering, and operates in the industry, energy and healthcare sectors. For more than 160 years, Siemens has built a reputation for leading-edge innovation and the quality of its products, services and solutions. With nearly 400,000 employees in 190 countries, Siemens reported worldwide sales of $96.6 billion in fiscal 2007. With its U.S. corporate headquarters in New York City, Siemens in the USA reported sales of $19.8 billion and employs approximately 70,000 people throughout all 50 states and Puerto Rico. For more information on Siemens in the United States, visit www.usa.siemens.com.

Contact:

Michael Krampe

(770) 751-2211

michael.krampe@siemens.com

Siemens Energy and Automation, Inc.,

3333 Old Milton Parkway,

Alpharetta, GA 30005

United States