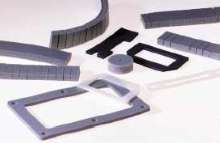

Silicone Foam Gaskets and Pads handle extreme temperatures.

Press Release Summary:

Silicone foam gaskets and cushioning pads, supplied in custom die cut, water jet cut, and slit-to-width configurations, are produced from liquid silicone rubber technology. Various grades are flame retardant to UL94V0 and UL94HF-1, and products are offered in 6 compression-force deflections from 0.75-18 psi and thicknesses from .032-1.0 in. They are suited for use as shock and cushioning pads in applications with temperatures from -67 to +392°F.

Original Press Release:

Silicone Foam Die Cut Gaskets and Cushioning Pads

Philadelphia, Pa. - Stockwell Rubber Company announces the availability of silicone foam gaskets and cushioning pads supplied in custom die cut, water jet cut and slit-to-width configurations. Silicone Rubber generally provides resilience, high temperature stability and inertness unavailable in any other elastomer. Silicone Foams are produced from new liquid silicone rubber technology, and many grades are flame retardant meeting UL94V0 and UL94HF-1. These flame retardant properties are often required for gaskets and cushioning pads in Telecommunications Equipment, Medical Diagnostic Equipment, Aircraft and Transportation, High Voltage Power Equipment and Controls. Stockwell has teamed up with Rogers Corporation and St. Gobain Performance Plastics to provide a full line of silicone foam products in six compression-force deflections, ranging from ultra soft (0.75 psi) to extra firm (18 psi). The thickness range is .032" through 1.0" thick, and special gauges can be attained by bonding layers using low viscosity silicone bonding adhesives. The excellent compression set properties of silicone foam make it ideal for shock and cushioning pads in applications where temperature extremes (-67° F to 392° F) are anticipated. Stockwell Rubber Co. applies over ten acrylic and silicone based pressure sensitive adhesives to their silicone foam product line. The company maintains a full inventory to support fast turn prototyping requirements - often utilizing their water jet cutting stations to produce parts from customer supplied Autocad dxf and dwg files. For complete information on the company's offerings in Silicone Foams, other silicone rubber products, molding and fabrication capabilities, contact Stockwell Rubber Company, Inc. Stockwell Rubber Company, Inc. 4749 Tolbut Street Philadelphia, PA 19136 (215) 335-3005 (215) 335-9433 fax Email: service@stockwellrubber.com Website: www.stockwell.com SR92 Rev 12-30-2004