Screen Changer keeps media flowing through filter.

Press Release Summary:

Big Screen automatically changes screens when filter clogs up with particles without slowing production. Actuator moves screens, bringing one which is to be exchanged outside screen body and clean one into flow area. While one screen is outside body it can be cleaned and prepared for next exchange. Changer accommodates screen sizes from 2 to 72 in. dia with different hole sizes, different spacing and different face to face dimensions.

Big Screen automatically changes screens when filter clogs up with particles without slowing production. Actuator moves screens, bringing one which is to be exchanged outside screen body and clean one into flow area. While one screen is outside body it can be cleaned and prepared for next exchange. Changer accommodates screen sizes from 2 to 72 in. dia with different hole sizes, different spacing and different face to face dimensions.Original Press Release:

Big Screen (TM)

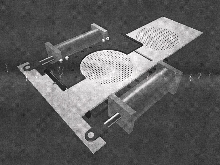

Stainless Valve Company together with Alexander Thibodeau of Mead, Steve Hogg have developed an automatic screen changer to remove solids from a flow media down to a certain particle size. When the screen should clog up with particles and the media does not flow anymore the clogged screen is replaced by a clean one without stopping production, just pressing a button.

If you have to stop production, take flanges loose, and replace screens, the Big Screen below will save much downtime.

The actuator moves the screens, bringing the one, which is to be exchanged, outside the screen body and at the same time the clean one into the flow area. While the one screen is outside the body it can be cleaned and prepared for the next exchange.

An example for the application of such a screen is the vent on the steaming vessel. In this case the Big Screen features for example a screen pattern of 1/4" diameter holes on a 1/2" square centerlines, the cut rings, which shear the protruding fibers from the screen surface, glass filled PTFE screen guides, expanded PTFE rope packing, and tandem actuators with 8000 lbs. of force for a 18" screen.

Another option is a feature of the Big Screen, which allows any accumulation of fines (smaller than the screen opening size) above the horizontal screen blade to be returned to the space below the screen when screens are exchanged.

For other applications different screen sizes (2" to 72" diameter) with different hole sizes, different spacing and different face to face dimensions can be selected.

There are other possible applications like a back up screen behind the rotary screen for the recovery boiler, reducing possible plugging of the heat exchangers and burners.

P.S. The Big Screen -is part of the SVC product family, i.e. Big Blow77 Stargate O-Port