Rotary Encoder is designed for large shafts.

Press Release Summary:

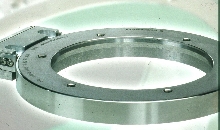

Designed for shafts with axes requiring accuracies to approximately 10 angular seconds, ERM 280 modular rotary encoder with magnetic scanning, features 20mm high scanning head. Magneto-resistive scanning permits shaft speeds up to 24,000 rpm, and is available for shaft diameters up to 295 mm (11.6 in.). Encoder features protection class IP 66. ERM 280 is mainly used on C axis of lathes, quill drives and electric motors for machine tools.

Designed for shafts with axes requiring accuracies to approximately 10 angular seconds, ERM 280 modular rotary encoder with magnetic scanning, features 20mm high scanning head. Magneto-resistive scanning permits shaft speeds up to 24,000 rpm, and is available for shaft diameters up to 295 mm (11.6 in.). Encoder features protection class IP 66. ERM 280 is mainly used on C axis of lathes, quill drives and electric motors for machine tools. Original Press Release:

Heidenhain's Rotary Encoder for Large Hollow Shafts

HEIDENHAIN's Rotary Encoder for Large Hollow Shafts

SCHAUMBURG, IL - (October 2001) - For use on large shafts with axes requiring accuracies to approximately 10 angular seconds, or in very contaminated environments, HEIDENHAIN presents the new ERM 280 modular rotary encoder with magnetic scanning. This new ERM 280, introduced last month at the EMO 2001 trade show, is mainly distinguished by its significantly smaller scanning

head, whose height was reduced from 40 mm to 20 mm.

The ERM 280 is mainly used on the C axis of lathes, quill drives and electric motors for machine tools. This encoder with magneto-resistive scanning permits shaft speeds up to 24,000 rpm, and is available for shaft diameters up to 295 mm (11.6 in.). Mounting is quick and easy, and no calibration effort is necessary. The

encoder features protection class IP 66.

For the magnetic scanning principle of the ERM 280, a measuring standard with a MAGNODUR® grating is used, which is scanned with magneto-resistive sensors. The special geometric arrangement of the resistive paths within the sensors ensures a high signal quality, which is a precondition for the smallest possible deviations within one signal period, and is therefore responsible for the high control quality of the ERM 280.