Robots/Rotary Tables grind, polish, and buff.

Share:

Press Release Summary:

Robotic Cells and Rotary Tables incorporate vision systems for handling multiple shape parts for large or small lots. Users may choose Motoman or ABB robots as well as Allan Bradley or Siemens controls. Machines are for stainless steel, carbon steel, and aluminum. Applications include welded fabrications, lighting fixtures, plumbing fixtures, hardware, furniture, and anywhere robotic or rotary table grinding, polishing, and buffing is required.

Robotic Cells and Rotary Tables incorporate vision systems for handling multiple shape parts for large or small lots. Users may choose Motoman or ABB robots as well as Allan Bradley or Siemens controls. Machines are for stainless steel, carbon steel, and aluminum. Applications include welded fabrications, lighting fixtures, plumbing fixtures, hardware, furniture, and anywhere robotic or rotary table grinding, polishing, and buffing is required.Original Press Release:

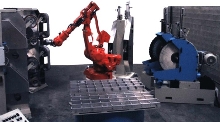

Perform the Work of 5 People Grinding, Polishing and Buffing with CIMID's Robotic Cells and Rotary Tables

ORANGE, NEW JERSEY, June 6, 2002 - No sick days and no coffee breaks, CIMID's Robotic Cells and Rotary Tables get the grinding, polishing and buffing jobs done. These are innovative work cells for individual solutions from single station to multiple stations. No need for second or third line suppliers because all design and manufacturing of the cells is done in-house.

These robots and rotary tables grind, polish and buff various shapes. The machines incorporate vision systems for handling multiple shape parts for large or small lots. When changing the part shape, it may necessitate the changing of the tooling head, which is quick and easy. Fixturing is designed in-house.

The design team lets the customer choose Motoman or ABB robots as well as Allan Bradley or Siemens controls. These machines are supplied in the customer's electrics and dust extraction ready.

These machines are for stainless steel, carbon steel and aluminum. Applications for these machines include welded fabrications, lighting fixtures, plumbing fixtures, hardware, furniture, medical implants, cutlery and anywhere robotic or rotary table grinding, polishing and buffing is required.

For more information, please visit our website at www.cimid.com. Or you can contact CIMID Corporation at 973-672-5000 or via e-mail at sales@cimid.com.