Rivet Strips speed conveyor belt splicing.

Press Release Summary:

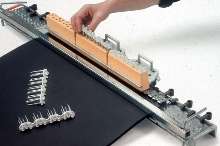

Flexco® Rapid Loader(TM) Collated Rivet Strips facilitate installation of Flexco SR(TM) Rivet-Hinged and BR(TM) Butt-Rivet conveyor belt fasteners. Plastic strips hold 4 sets of 5 rivets in pattern required for SR/BR installation. Each block of 20 rivets, which installs 4 adjacent fasteners, loads in approximately 7 seconds. Strips are color-coded to assure correct rivet size selection for belt thickness and for consistency across splice.

Original Press Release:

New Flexco® Rapid Loader(TM) Collated Rivet Strips Speed Conveyor Belt Splicing, Reduce Sizing Errors

DOWNERS GROVE (IL), APR. 30, 2004 -- New Flexco® Rapid Loader(TM) Collated Rivet Strips (patented) speed and simplify installation of Flexco SR(TM) Rivet-Hinged and BR(TM) Butt-Rivet (solid plate) conveyor belt fasteners by loading multiple rivet sets in only 20% of the time needed to load the same number of rivets individually.

Plastic strips hold four sets of five rivets in the pattern required for SR/BR installation, ready for simultaneous loading into 20-rivet MSRT or MBRTA multiple guide-block installation tooling. Each block of 20 rivets, which installs four adjacent fasteners, loads in approximately seven seconds using Rapid Loader strips, compared with approximately 35 seconds when rivets are loaded individually. Total time saved depends upon belt width or total number of guide blocks used. Strips are color coded to assure correct rivet size selection for belt thickness and for consistency across the splice. They also eliminate rivet counting and possible time lost retrieving spilled rivets.

After insertion into guide blocks, rivets are released from the Rapid Loader strip as each set is tapped with the installation hammer. With blocks pre-loaded, users hammer-drive five rivets at a time across the belt's width, using a special five-pronged drive rod. The self-setting rivets feature breakaway pilot nails that penetrate the belt without damaging or weakening its carcass, and allow installation to be completed entirely from the belt's topside.

Rapid Loader plastic strips narrow to a thin checkpoint between each five-rivet set, easily broken by hand flexing for tasks requiring fewer than four sets.

All eight sizes of Flexco SR rivets, in steel or stainless steel, are available in Rapid Loader strips packaged 60 four-set strips (1200 rivets) per high-visibility yellow bucket -- enough rivets to complete two 48" (1200mm) splices.

Flexco SR Rivet-Hinged fasteners provide easily separable hinged-plate splices in belts ranging from 7/32" to ll/16" (6-17mm) thick, while BR Butt-Rivet fasteners provide tightly butted, sift-free solid plate splices in belts from 7/32" to 15/16" (6-24mm) thick, both types suited for belts with mechanical fastener ratings up to 800 pounds per inch (140 kN/m) of width.

Flexco, headquartered near Chicago, IL/USA, services the world's belt conveyors through subsidiaries operating in California, Michigan, Mexico, England, Germany, Australia, New Zealand and South Africa. Founded in 1907 and certified under ISO-9000 International Standards for Quality Management, the company markets its broad line of products through a worldwide network of distributors, under the brand names Flexco®, Alligator®, Clipper®, Tatch-A-Cleat®, and Flex-Lag®, and the trade name Rockline(TM).

For more information, visit Flexco's website at www.flexco.com, or contact the Customer Service Department, Flexco, 2525 Wisconsin Ave., Downers Grove, Illinois, 60515-4200, USA. Phone (630) 971-0150; fax (630) 971-1180. For free literature only, call the Literature Hotline at 1-800-872-5216.