Pinless Syphon Elbow suits steam-heated rotating cylinders.

Press Release Summary:

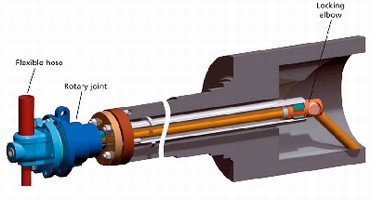

Featuring integral locking mechanism that secures elbow into position, 45° Syphon Elbow is intended for installation on blind rolls or rolls with hand hole access. All components of elbow are constructed of stainless steel to provide corrosion-resistance. In addition, 45° angle results in less cantilever weight compared to long bent syphon pipe, causing less stress on horizontal syphon pipe thread connection.

Original Press Release:

Kadant Johnson Introduces Pinless Syphon Elbow

Three Rivers, Mich., August 4, 2008 - Kadant Johnson Inc., a subsidiary of Kadant Inc. (NYSE:KAI), has introduced the first pinless syphon elbow for use in steam-heated rotating cylinders. The patent-pending design features an integral locking mechanism that secures the elbow into position and increases the robustness of the syphon system. The 45 degree locking syphon elbow is intended for installation on blind rolls or rolls with hand hole access. All components of the syphon elbow are constructed of stainless steel to provide corrosion-resistance and extended operating life. In addition, the 45 degree angle results in less cantilever weight compared to a long bent syphon pipe causing less stress on the horizontal syphon pipe thread connection. Also, the hinge pin, the weakest link in conventional syphon elbows, has been eliminated. The new locking syphon elbow can be used with existing syphon pipes and Kadant Johnson steam joints. Kadant Johnson Inc., based in Three Rivers, Michigan, is a leading provider of rotary joints, precision unions, and fluid handling systems to process industries, where they optimize heat transfer in rotating cylinders and integrate fluid handling systems.