Peeler utilizes dry peel operating principles.

Press Release Summary:

U-Bed High Speed Peeler offers roll speeds up to 1000 rpm. Peel is flushed out of rotation brushes by centrifugal force, reducing need to use water. Two-way cover lifts with pneumatics and opens from either side for cleaning access. U-Bed processes all root crops including carrots, dry scrubbing potatoes after steam peeling, and potato chips for fresh product peeling.

Original Press Release:

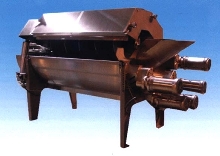

Lyco's New High Speed U-Bed Peeler For Carrots & Potatoes Has Higher Throughput, More Capacity In Smaller Footprint

Lyco Manufacturing announces its new patented U-Bed Peeler, the High Speed Peeler, designed for greater processing volume and production throughput of all root crops including carrots, dry scrubbing potatoes after steam peeling, and potato chips for fresh product peeling. This unit has far more capacity than a traditional U-Bed peeler. Featured in Lyco's booth #7202 at the IEFP, Chicago, Nov. 3-7, the high speed peeler also provides wastewater reduction benefits from its Dry Peel operating principles.

Roll speeds as high as 1000 RPM are possible on this new U-Bed peeler. At these high speeds, peel is flushed out of the rotating brushes by centrifugal force, thus reducing the need to use water to flush peel. These enhanced Dry Peel results mean less peel to haul away and less wastewater to handle.

Engineered for rugged yet simple operation, Lyco's High Speed Peeler features less complexity and lower maintenance requirements than rotating cage machines. A two-way cover lifts effortlessly with pneumatics and opens from either side for easy cleaning access. The High Speed Peeler is CIP compatible.

At IEFP, Lyco will also be displaying its 72-inch diameter Simulator, designed for aiding customers in process development of continuous cooking, pasteurizing or cooling processes. The Lyco Double Drum Separating Screen and Screw Press will also be on display.

Lyco Manufacturing, headquartered in Columbus, Wisconsin USA, is a leading manufacturer of high-quality commercial-grade equipment for the food processing industry, providing systems for vegetables, pasta, poultry and meat products. Lyco's innovations include high capacity blanchers, combination cooker/coolers, pasteurizers, root crop peelers, snap bean equipment, and wastewater screens. Lyco's Action Team assists customers to improve operational needs, and includes senior level managers from Lyco's marketing, engineering and manufacturing disciplines.

For more information, contact:

Steve Hughes

Lyco Manufacturing

115 Commercial Drive, P.O. Box 31

Columbus, WI 53925 USA

Tel: 920 623 4152

Fax: 920 623 3780

E-mail: steve.hughes@lycomfg.com

www.lycomfg.com