Multiphysics Modeling Software offers 3 discipline specific modules.

Press Release Summary:

COMSOL Multiphysics v4.3 includes 3 discipline-specific add-on modules, fast meshing, and double dogleg solver for mechanical contact and highly Add-ons include Nonlinear Structural Materials Module, Pipe Flow Module, and Corrosion Module. Meshing algorithm creates default mesh in 30 sec on standard dual core workstation. Double dogleg solver allows for tagging load cases to facilitate setup of extensive structural mechanics studies.

Original Press Release:

COMSOL Multiphysics Version 4.3 Now Available

Burlington, MA - Today COMSOL announces the 4.3 release of COMSOL Multiphysics, its industry-leading software environment for modeling and simulating any physics-based system. COMSOL Multiphysics 4.3 empowers engineers, researchers, and scientists with powerful new modeling tools and fast simulations that further establish COMSOL as a leading innovator in simulation for electrical, mechanical, fluid flow, and chemical applications. Major new capabilities introduced in version 4.3 include three new discipline-specific add-on modules, fast and powerful meshing, a new "Double Dogleg" solver for mechanical contact and highly nonlinear simulations, and numerous user-inspired enhancements. COMSOL Multiphysics 4.3 is available immediately from COMSOL sales offices worldwide.

Enhancements and upgraded functionality span the entire COMSOL product suite. With the debut of three new discipline-specific add-on modules - the Nonlinear Structural Materials Module, the Pipe Flow Module, and the Corrosion Module - COMSOL now offers 30 products for the simulation of multiphysics phenomena. The newest modules expand the COMSOL Multiphysics simulation platform with all-new user interfaces that help users solve the unique design challenges in each of these areas accurately and efficiently.

This geometric representation of a lung was imported using the COMSOL CAD Import Module. The meshing algorithm creates a default mesh in 30 seconds on a standard dual core workstation. Generating a coarser mesh takes 10 seconds, when Virtual Geometry operations are applied to minimize the influence of non-essential geometry edges and surfaces. Geometry courtesy of Prof. Thomas Royston and Ying Peng, Acoustics & Vibrations Laboratory, University of Illinois at Chicago.

User-inspired Developments

COMSOL users played a vital role in developing this new version. Their requests, suggestions, and feedback contributed significantly to the features that were ultimately implemented, making COMSOL Multiphysics 4.3 a true community effort.

"Our mission is to bring engineers and scientists reliable simulation tools that impact their day-to-day work, so their input is a crucial component of our product," said Bjorn Sjodin, VP of Product Management for COMSOL. "We're continually soliciting and receiving feedback from our user base, while pursuing that passion for innovation that COMSOL is known for."

The combined talent of COMSOL developers and users not only make this a major release, but many of the requested enhancements further increased the integration of COMSOL Multiphysics with the larger CAE community. For example, core modeling capabilities in version 4.3 have been updated and expanded significantly. Meshing is now both faster and more powerful, particularly when working with virtual geometry operations for shielding the automatic mesher from unnecessary geometric detail. Users working with imported meshes can now group existing mesh elements into new domains and boundaries, which makes it easy to assign boundary conditions and material properties wherever desired.

This nanotomography model of a lithium-ion battery microstructure was imported as a mesh. For enabling a boundary condition on one side of the structure, COMSOL 4.3's new Mesh Selection operations can group elements into a new geometrical boundary. This technique allows for importing previously meshed structures, including legacy meshes, which can then be used for any type of COMSOL Multiphysics simulation. The meshed model seen here is courtesy of Professor Likun Zho's research group at Indiana University-Purdue University, Indianapolis.

Users can now run multiple-parameter sweeps with easy specification of one, two, or more parameters - sweeping for all of them or just a subset of them. Visualizations of results from these parameter sweeps can be easily selected to include combinations of the swept parameters in a single presentation. New Cluster Sweep and Batch Sweep user interfaces facilitate defining massively parallel and independent parametric sweeps.

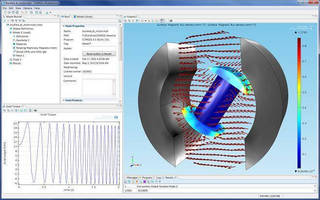

Version 4.3's modules for electrical, mechanical, fluid flow, and chemical simulations have all been updated with exciting new features and capabilities. Responding to multiple requests, COMSOL implemented a user interface within the AC/DC Module for modeling 3D rotating machinery. Users benefiting from this new functionality include those working on applications for generators, brushless motors, radial and axial flux machinery along with brushed DC electric motors.

The AC/DC Module now includes the ability to model rotating machinery in 3D. Here, a brushed DC motor simulated with the new 3D rotating machinery user interface is shown. Visualized are B-field, coil current, axial torque, and rotational angle.

Users of the Structural Mechanics and MEMS Modules will appreciate a new solver for mechanical contact and highly nonlinear simulations -- the "Double Dogleg" solver. New tools for tagging load cases have also been included for easier setup of extensive structural mechanics studies. The CFD Module introduces new, easy-to-use interfaces and added functionality for mass transport simulations influenced by turbulent mixing, while the Particle Tracing Module now incorporates particle-particle interaction and Brownian forces into its extensive list of supported functionalities.

Nonlinear Structural Materials Module

The new Nonlinear Structural Materials Module augments the mechanical capabilities of the Structural Mechanics and MEMS Modules by adding nonlinear material models. When the mechanical stress in a structure becomes large, certain nonlinearities in the material properties force the user to abandon linear material models. This situation also occurs in some operating conditions, such as high temperature. The new module adds elastoplastic, viscoplastic, creep, and hyperelastic material models. These are based on a new, extended framework for the constitutive laws which users can easily extend for their unique needs.

"We asked COMSOL to implement the Arruda-Boyce hyperelastic model and anisotropic Hill plasticity. These two material models accurately represent the constitutive behavior of a wide range of elastomers and metals, respectively," said Nagi Elabbasi, a Senior Engineer at Veryst Engineering and an experienced COMSOL user. "We are excited to have these new capabilities now available in version 4.3."

In this classic benchmark, a circular bar is subjected to a uniaxial tensile test, resulting in large deformations. The bar experiences large-scale necking and plastic deformation across its central cross-sectional region. This simulation is made possible by the large strain plasticity option available in the Nonlinear Structural Materials Module and the new, very powerful Double Dogleg solver.

Pipe Flow Module

The new Pipe Flow Module will interest engineers who design and optimize the pipe and channel networks used in turbines, building ventilation systems, chemical and material manufacture processes, and in the oil and gas industry. The module enables efficient simulations of 1D fluid flow, heat and mass transfer, hydraulic transients, and acoustics. The Pipe Flow Module's simulation results can be integrated into 2D and 3D models of network components, yielding the velocity, pressure variation, and temperature along the pipes and channels in the network.

Cooling of a steering wheel injection mold. The new COMSOL Pipe Flow Module allows for efficient simulation of the cooling channels using 1D pipe non-isothermal flow. This is fully coupled to the heat transfer simulation of the mold and polyurethane part, which was imported as a CAD geometry.

Corrosion Module

Corrosion is everywhere and is an especially important concern for off-shore structures, ships and submarines, aerospace, and automotive parts. George F Hays, Director General of the World Corrosion Organization, estimates that 3% of the worldÃs GDP is lost every year due to corrosion. (See the report "Now is the Time" www.corrosion.org/images_index/nowisthetime.pdf )

The new COMSOL Corrosion Module offers specialized user interfaces to model the electrochemical processes that lead to corrosion. Using the Corrosion Module, engineers who want to mitigate these processes can gain powerful insights into how structures might corrode under certain conditions and how structures can be protected. The module includes the physics required to model galvanic, pitting, and crevice corrosion as well as cathodic and anodic protection.

Galvanic corrosion of a magnesium alloy (AE44) connected to mild steel in a salt-water solution. The electrode material removal is represented with a moving mesh, an important variable to be considered when performing such simulations.

This May, corrosion experts gathered at the COMSOL headquarters in Burlington, MA, to be the first to put their hands on the Corrosion Module. "I am new to COMSOL Multiphysics, and I made the decision to become a user with the debut of the Corrosion Module," says Staff Research Engineer Lei Chen with UTRC, Hartford, CT, who attended the corrosion modeling training course. "This training was a great opportunity for me to get an introduction to the modeling of corrosion. In particular, I am planning to use the module for the study of localized corrosion processes. The Corrosion Module makes COMSOL able to address the simulation needs in major industries such as material protection and coating."

Empowering COMSOL Users with More Speed and New Modeling Tools

COMSOL Multiphysics version 4.3 is a major release. It has been built with the combined knowledge and experience of COMSOL's development teams and hands-on practitioners of modeling and simulation from around the world. With its three new expansion modules, this version also empowers users in major industries for the first time with the innovation potential of an easy-to-use yet powerful multiphysics simulation platform that operates the way they think. COMSOL Multiphysics version 4.3 delivers its users simulation products for boosting engineering efficiency.

Highlights of Version 4.3

About COMSOL

COMSOL Multiphysics is a software environment for the modeling and simulation of any physics-based system. A particular strength is its ability to account for multiphysics phenomena. Optional modules add discipline-specific tools for mechanical, fluid, electromagnetics, and chemical simulations, as well as CAD interoperability. Founded in 1986, the company has U.S. offices in Burlington, MA, Los Angeles, CA, and Palo Alto, CA. International operations have grown to include offices in the Benelux countries, Denmark, Finland, France, Germany, India, Italy, Norway, Sweden, Switzerland, and the United Kingdom. Independent distributors of COMSOL Multiphysics are located in Australia, China, Egypt, Greece, Hungary, Israel, Japan, Korea, Malaysia, Poland, South Africa, the Czech Republic, Spain, Taiwan, and Turkey. Additional information about the company i! s available at www.comsol.com.

COMSOL and COMSOL Multiphysics are registered trademarks of COMSOL AB. Capture the Concept and COMSOL Desktop are trademarks of COMSOL AB. Other product or brand names are trademarks or registered trademarks of their respective holders.

COMSOL, Inc.

1 New England Executive Park

Ste 350

Burlington, MA 01803

Tel: 781-273-3322

Fax: 781-293-6603

Web: www.comsol.com

E-mail: info@comsol.com

COMSOL Contact:

Lauren Sansone, Marketing Manager

lauren.sansone@comsol.com

Note to editors: Hi-res images of COMSOL Multiphysics are available for download at www.comsol.com/press/gallery.

This screen shot shows an oil rig structure immersed in seawater and protected by 52 sacrificial aluminum anodes. Before deploying the anodes, engineers would use the new COMSOL Multiphysics Corrosion Module to optimize the position of each anode for the best possible corrosion protection. Visualized is the electrolyte potential on the surface of the structure.