Modular Pay-Off handles fine and very fine wire.

Share:

Press Release Summary:

Motorized Payoff utilizes low-stress, French Curve unwind path and accommodates fine wire materials from .006-.050 in. diameter. It features snag detection sensor and shutdown signal output, controlled back tension for precise control of any downstream straightening process, as well as built-in loop control reservoir for up to 4 ft of pulled wire. Accommodating up to 60 lb of material, payoff can be spool or coil configured with standard OD of 24 in.

Original Press Release:

New Motorized 'Fine Wire' Payoff

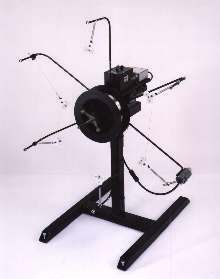

TAK Enterprises announces the introduction of a new motorized payoff for fine and very fine wire. The modular payoff is designed to accommodate a wide range of fine wire materials like Gold, Tungsten, Silver, Aluminum, Molybdenum, Nitinol(TM), Stainless Steel, Platinum, etc. from .006" to .050" (0.15mm to 1.25mm) in diameter and utilizes a low stress "French Curve" unwind path that significantly reduces the typical "bird nesting" wire condition.

The advanced features include "controlled back tension" for more precise control of any down stream straightening process as well as a built in loop control "reservoir" of up to 4 feet of "pulled" wire that also acts as a clutch during startup and incremental feed; controlling the material output and preserving the physical state of the material. Each wire guide rests on a "free floating" precision bearing sleeve that automatically tracks with the lay down of the material on the spool rather then forcing the wire to a set pickoff point. This method significantly reduces the effects of "wire pinches" and "crossovers". The new guide design utilizes a triangular arranged set of low friction "V" shaped plastic rollers with and embedded ceramic channel that allows the wire to "roll" through the guide points arid is especially helpful in abrasive or very low tensile wire applications.

Lastly, the payoff is equipped with a "snag" detection sensor and shutdown signal output that eliminates the lost production time as a result of having to re-thread the payoff, the wire straightener and any other down stream wire processing equipment.

The payoff takes very little floor space with a footprint of only 57" ( H ) by 43" ( W ) by 43" ( D ), can be either spool or coil configured with a standard OD of 24" and an optional 30" capacity, has height adjustments, can accommodate up to 60 pounds of material, has a DC gear motor drive with controls for forward and reverse feeding with adjustable rates up to 83 RPM and is micro-switch activated. The unit runs on 110 VAC.

As an ISO 9001 certified manufacturer of precision miniature parts and linear material processing equipment, TAK Enterprises, of Bristol, CT, has been supplying precision and premium grade wire straighteners, payoffs/decoilers, wire cleaner / lubricators and feed & cutoff systems since 1981. Additional product information can be found on our web site www.takenterprises.com or by contacting Norman A. Pierce VP sales & Marketing@ 860-583-0517 or via e-mail at tak@takenterprises.com.