Lubrication System is designed for stamping presses.

Press Release Summary:

MicroCoat Lubrication System ensures that stock is always coated with even film of oil. It uses precision spray valves and LVLP (Low Volume Low Pressure) air to apply consistent coat of oil without dry spots, dripping or waste. Valve operation is regulated with pneumatically operated controller. Individual flow controls allow each valve's output to be adjusted independently and provide control over amount of oil applied.

MicroCoat Lubrication System ensures that stock is always coated with even film of oil. It uses precision spray valves and LVLP (Low Volume Low Pressure) air to apply consistent coat of oil without dry spots, dripping or waste. Valve operation is regulated with pneumatically operated controller. Individual flow controls allow each valve's output to be adjusted independently and provide control over amount of oil applied. Original Press Release:

Stock Lubrication System Reduces Downtime on High-speed Stamping Presses

East Providence, RI USA -- The MicroCoat lubrication system reduces downtime and maintenance on high-speed stamping presses by ensuring that stock is always coated with an even film of oil.

Benefits of controlled oil application include longer die life and less tool damage, less slug pulling and die packing, and oil savings of up to 70%.

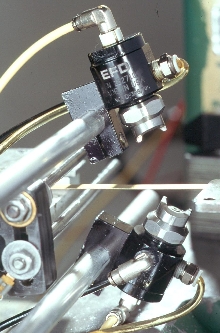

Unlike drip, pad, and roller systems that apply too much or too little oil, the MicroCoat uses precision spray valves and LVLP (Low Volume Low Pressure) air to apply a consistent coat of

oil without dry spots, dripping or waste. The system's uniform coverage reduces maintenance and downtime by keeping tools sharper up to 3 times longer and eliminating mist and puddles in

the pressroom.

Valve operation is regulated with a pneumatically operated controller that makes it easy to achieve optimum results with different metals, lubricants and press speeds. Individual flow

controls allow each valve's output to be adjusted independently and provide exceptional control over the amount of oil applied. The proper lubrication level for any job can be established in just a few minutes and will remain consistent for the entire press run without further adjustment.