Low Profile SMT Target Discs mate with spring pins.

Press Release Summary:

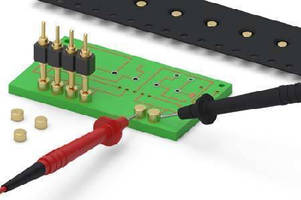

Measuring .078 in. in diameter and .055 in. ± .002 in. tall, Model 1578-3-57-15-00-00-03-0 SMT Disc features flat surfaces on both sides with virtually no burrs. Flat surfaces are suitable for surface mount soldering and as conductive mating surface for spring-loaded pins and connectors as well as test probes. Machined from brass, discs come standard with 10 µin. hard gold finish with nickel under-plate. Discs are typically placed on solder pasted PCB pads and then subjected to reflow soldering.

Original Press Release:

Mill-Max Introduces Unique Low Profile SMT Target Discs

Mill-Max is excited to announce a new addition to its family of spring pin mating products. This low profile SMT disc shaped terminal is perfect for applications where vertical space is at a premium.

The new 1578-3-57-15-00-00-03-0 SMT disc is .078" (1,98 mm) in diameter and only .055" +/-.002" (1,4 mm +/- 0,0508 mm) tall. Employing our precision-machining expertise we are able to achieve flat surfaces on both sides of the disc with virtually no burrs. The flat surfaces are ideal for surface mount soldering and as the conductive mating surface for spring-loaded pins and connectors as well as test probes. The discs are typically placed on solder pasted PCB pads and then subjected to reflow soldering. Once soldered the terminals are ready to be used as reliable, durable contact points.

The 1578-3's are packaged on tape & reel -- 16 mm wide x 8 mm pitch, 4,000 parts per reel -- making them simple to integrate into existing pick & place equipment and assembly processes. The tape packaging is per EIA-481-D.

These SMT target discs are machined from brass and come standard with a 10 u" hard gold finish with a nickel under-plate. Custom sizes are quickly and easily achievable via Mill-Max's high speed precision-machining processes. Other plating options, such as thicker gold or other materials, are also available. In addition, we offer many other styles of discrete target pins, which may better be suited to your application. As always, if you don't see what you need feel free to contact our technical support team to discuss your particular application and requirements.

For more information use the links to the right for additional product details, to find related products, or contact Mill-Max Technical Services for additional questions.