LM Guides and Ball Screws utilize caged ball technology.

Press Release Summary:

Measuring 976 x 540 x 300 mm, Type SNS300 LM Guide features 4-direction, equal load rating. Available in sizes up to 12025, Heavy Load Ball Screw Type HBN performs 100,000 cycles without problems when tested for durability under 118 kN load, 48 mm stroke, 3.8 m/min max conditions. Operation at higher ambient temperatures is identical at 20 and 80°C temperatures. Ball screw achieves increase in max nut rpm, 130,000 DN.

Measuring 976 x 540 x 300 mm, Type SNS300 LM Guide features 4-direction, equal load rating. Available in sizes up to 12025, Heavy Load Ball Screw Type HBN performs 100,000 cycles without problems when tested for durability under 118 kN load, 48 mm stroke, 3.8 m/min max conditions. Operation at higher ambient temperatures is identical at 20 and 80°C temperatures. Ball screw achieves increase in max nut rpm, 130,000 DN.Original Press Release:

THK Expands on Caged Technology Line with Larger Sized LM Guides and Ball Screws

Schaumburg, IL - (September 1, 2004) THK has literally expanded on the proven-performance of its caged technology LM Guides and Ball Screws with the introduction of its extra large line of products.

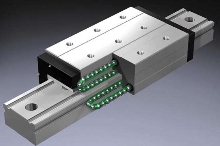

THK's new ultra large scale Type SNS300 LM Guide is the largest LM Guide with Caged Ball Technology. The SNS300 features a height of 300 mm, a block width of 540 mm, a block length of 976 mm and a rail width of 300 mm. The Type SNS features a four-direction, equal load rating.

THK's Heavy Load Ball Screw Type HBN, has an extremely large load capacity due to the optimized design of its internal structure. In heavy load durability tests (118kN load, 48 mm stroke, 3.8m/min max), the Type HBN performed 100,000 cycles without any problems. Test operations at high ambient temperatures found movements to be identical at 20 degree and 80 degree C temperatures. The Type HBN has been proven to outperform hydraulic cylinders. Improved energy savings, superior positioning accuracy, clean operation, enhanced machine control and reduced maintenance all make the Type HBN interchangeable with, if not superior to, hydraulic cylinders. THK's ball screw achieves an increase in maximum nut rpm (130,000 DN). The Type HBN is available in sizes up to 12025.

THK's Caged Technology employs a synthetic resin cage with a patented curvature that cradles each ball and separates it from the next. The spaces between the rolling elements retain grease and act as a lubrication system for long-term maintenance-free operation. Other Caged Technology benefits include reduced noise, increase speed and accuracy of motion, high rigidity, reduced dust generation and smooth movement.

The overwhelming success of THK's caged technology has propelled the expansion of caged technology throughout the product line. THK is also expanding their product offering to include larger and smaller sizes as well as new materials and technology to achieve superior results in the most demanding applications.

To learn more, visit their IMTS Booth #D-4305, log on to www.thk.com or contact THK America, Inc., 200 E. Commerce Dr., Schaumburg, IL 60173, Phone: (847) 310-1111, Fax: (847) 310-1182, e-mail: chicago@thk.com.