Tube / Pipe / Hose Cutters and Cutting Machinery

Laser Cutting System handles variety of tubes and pipes.

Press Release Summary:

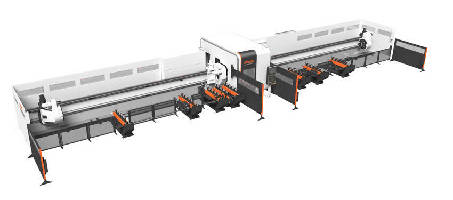

Equipped with 6-axis laser and 2.5 or 4 kW resonator, 3D FABRI GEAR Mk II cuts round, square, rectangular, and triangular tubes and pipes, as well as I/H beams, C-channel, angle iron, and user-defined shapes from mild or stainless steel. Model 220 handles pipe diameters up to 8.6 in. at rapid traverse rate of 3,937 ipm, while Model 400 processes pipe up to 16 in. dia. Once material is set into loading station, machine automatically performs material handling, 3D laser cutting, and unloading.

Original Press Release:

Mazak Introduces 3D FABRI GEAR Mk II for Tube, Pipe and Structural Applications

Elgin, Illinois, – Mazak Optonics has released a new 3D FABRI GEAR Mk II machine for an expanded range of laser-cut tube, pipe and structural applications. Available in a 220 and 400 model with a 2.5 or 4kW resonator, the 3D FABRI GEAR Mk II cuts a wide variety of tubes and pipes including round, square, rectangular and triangular. It can also process I and H beams, C-channel, angle iron and additional user-defined shapes from mild or stainless steel. This extensive range of capabilities makes the machine ideal for many various industries.

Featuring a powerful, high-precision 6-axis laser, the 3D FABRI GEAR Mk II can handle larger, longer, thicker and heavier material than similar machines. It also has improved processing speeds, tighter tolerances and can be used for drilling and tapping.

The 220 Mk II model can process a round pipe diameter of up to 8.6 inches at a rapid traverse rate of 3,937 IPM. For large material jobs, the 400 Mk II can process a round pipe diameter of up to a 16”.

The 3D FABRI GEAR Mk II also offers a 10% faster cycle time due to improved sequencing and simultaneous unit operations for the loading/unloading cycles. Once material is set into the loading station, the machine automatically performs the material handling, 3D laser cutting and unloading of finished work pieces.

In accordance with Mazak’s commitment to improving the environment, the 3D FABRI GEAR Mk II features a new eco-friendly resonator to reduce gas and electricity consumption by 50% and 10%, respectively. In addition, all machines are produced in an ISO 14001 certified facility.

About Mazak Optonics

Mazak Optonics Corporation is a major supplier of laser-cutting systems, offering 50 laser models and leading the industry in the implementation of emerging laser technologies. The company’s 50,0000 sq. ft. North American Headquarters are located in Elgin, Illinois, and feature a 30,000 sq. ft. laser technology center housing up to 18 machines for demonstrations and training. Mazak Optonics is part of Yamazaki Mazak Corporation (Oguchi, Japan), the global leader for the manufacture of machine tools and systems for the precision machining of metal parts, including CNC turning centers, horizontal and vertical machining centers, Multi-Tasking machining centers, turnkey cells and software solutions. The North American Headquarters for Yamazaki Mazak are located in Florence, Kentucky. For more information on Mazak Optonics’ products and solutions, visit www.mazakoptonics.com, email sales@mazaklaser.com or call 847.252.4500.