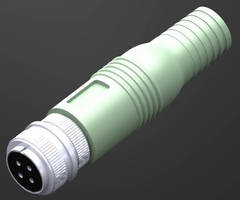

IP67 Waterproof Connectors are available in overmolded design.

Press Release Summary:

Built to withstand harsh applications, standard and custom IP67-rated connectors feature watertight seal and are designed to withstand shock, vibration, and corrosion. Injection over-molding, which entails 2 different shots (pre-mold and final mold), increases ruggedization. While pre-mold, made of hard durometer polypropylene, serves as protective encapsulater and helps keep contacts in place, final mold is available in various thermoplastics, such as PVC and rubber.

Original Press Release:

Injection Over-Molding for IP67 Waterproof Connectors

In the world of connectors there are thousands of styles, configurations and functionality types. IP67–rated connectors come in both standard and custom solutions that are built to withstand some of the harshest applications.

IP67 connectors are intended to house the internal connections with a watertight seal and are typically designed to withstand shock, vibration and corrosion. These types of connectors are common place for many industrial and electronic products used in environmentally challenged applications.

To make these already robust connectors even more rugged the process of injection over-molding can be a value added process. The process of over-molding usually entails two different “shots” which are the pre-mold and final mold. The pre-mold serves as a protective encapsulater which is made of a hard durometer polypropylene. The polypropylene pre-mold helps to keep the contacts in place and can be thought of as the skeleton for the final mold. The final mold is both an aesthetic and functional attribute to the assembly. The final mold can be done in various thermoplastics such as PVC and rubber. Some aesthetic attributes of a final mold are color, logos and geometrical angles that give an assembly a unique appearance. Some functional attributes of an over-mold are an EDM texture for grip and a strain relief which minimize tension and stress on the cables flex region. The combination of an IP67 connector and the benefits of injection over-molding provide a very dynamic assembly with multiple benefits.

A US based manufacturer ISC Engineering has bundled their industry know how to bring a solutions based approach to the cable assembly business. They are a “one stop shop” for tooling, assembly and over-molding of IP67 and similar type connector products. They specialize in custom solutions for high mix low volume assemblies and have rapid prototype capabilities which is all done in Chino, CA. To learn more about IP67 connectors and overmolding solutions visit www.iscengineering.com or talk direct to an engineer 909-203-1125.