Image Analysis Software enables one-pass product inspection.

Press Release Summary:

Used to detect and reject contaminants and product defects inside closed packages, SimulTask™ PRO x-ray inspection software incorporates seal integrity, fill level inspection, check weighing, and component count features. These capabilities, maximizing uptime while minimizing investment, let food manufacturers improve overall equipment effectiveness (OEE) and complete multi-level product inspection in one pass within seconds.

Original Press Release:

Product Inspection in One Clean Sweep with Eagle

Image analysis software SimulTask PRO inspects products for contaminants, product and packaging defects, check weighs and counts components

Tampa, Florida – Eagle Product Inspection has taken its image analysis software - SimulTask™ PRO – to the next level of product inspection. The latest enhancements of the x-ray inspection software, which detects and rejects contaminants and product defects inside closed packages, now incorporates seal integrity, fill level inspection, check weighing and component count features. These advanced capabilities enable food manufacturers to improve overall equipment effectiveness (OEE) and complete multi-level product inspection in one pass, in seconds. This maximizes uptime and eliminates the need for businesses to invest in additional inspection technologies.

Simon King, Global Head Sales, Service and Marketing, Eagle Product Inspection commented: “The question of how to manage production line costs without compromising product quality and safety is foremost in our industry. We know that sending out substandard products is damaging to food manufacturers because of the time and expense involved in product recalls, potential harm to consumers, and loss of brand reputation. In fact, the loss of sales due to bad product is often much greater than organization’s realize. By advancing our SimulTask™ PRO software, multiple inspection technologies now work together to check for contaminated materials, verify weight and fill levels, and ensure seal integrity. As such, manufacturers can be confident that only high-quality product exits their facility at a reduced cost per pack price, due to the lower initial investment of four-in-one product inspection software.”

SimulTask™ PRO image analysis software allows simultaneous x-ray inspection of different products within many formats and sizes of packaging. The system inspects for a number of contaminants, such as metal, glass, dense plastics and calcified bone, in packaged products on multiple production lanes at high-throughput speeds. Similarly, the SimulTask™ PRO check weighing feature examines the density of the product which is then used to calculate the total weight while also verifying the presence or absence of specific items, and verifying count. This intelligent software can also weigh separate compartments in packaging such as ready meals. Automatically removing packages that fall outside the pre-agreed limits keeps processes optimized while helping manufacturers comply with local and food safety global regulations governing the net contents of packaged goods which identify the minimum and average required content as indicated on the package or label.

The third main product inspection issue is to guarantee that there are no product imperfections. Defects can occur when the product and/or package is exposed to extreme conditions such as moisture, freezing, thawing and salinity. Varying atmospheric environments can cause deformations in the packaging, affect fill levels and seal integrity – all leading to consumer dissatisfaction and possible product recalls. The x-ray technology automatically identifies any abnormalities so the inadequate product can be instantly removed from the production line, reducing unscheduled downtime and safeguarding quality.

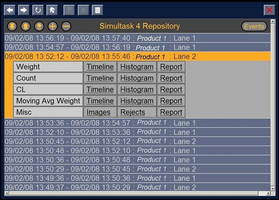

To optimize production efficiency and ensure consistent product quality across the manufacturing line, a simple user interface provides easy access to statistics and reports. Data specifying the weight of products, number of products inspected, amount of rejects and the breakdown of the reject types between contaminants and other defects are all captured real-time. This allows compliance with Hazard Analysis and Critical Control Points (HACCP) principles and food safety regulations. Moreover, the diagnostic capabilities of SimulTask™ PRO ensure complete control of the product inspection process, so proactive maintenance can be scheduled, further enhancing productivity.

About Eagle Product Inspection

Eagle Product Inspection is a pioneer in advanced x-ray inspection and fat analysis systems, delivering robust, market-leading technology and expertise to food and beverage processors and manufacturers around the world. The Eagle Product Inspection line of x-ray inspection systems evaluates in process and finished products for contaminants such as metal, glass, stone and bone while also having the ability to analyze the fat content of meat, count components, check seal integrity as well as measure mass and assess fill levels.

With its headquarters in Tampa, Florida, and local offices across the globe, Eagle Product Inspection machines meet today’s Hazard Analysis & Critical Control Points (HACCP) certification requirements. Eagle and its partners work in close collaboration to ensure that food and beverage manufacturers and their customers in turn can rest assured that the quality of every product is upheld.

Visit www.eaglepi.com for more information.

Contact:

Eagle Product Inspection

6005 Benjamin Road

Tampa, FLÂ 33634

Telephone: +1-877-379-1670

Email: eaglesales@eaglepi.com

Website: www.eaglepi.com