IDC-based Interconnect terminates copper, aluminum magnet wires.

Press Release Summary:

MAG-MATE insulation displacement crimp (IDC) interconnection system suits fractional horsepower motor manufacturers evaluating switch from copper to aluminium magnet wire. Able to terminate 34-12 AWG wire, UL-recognized product compensates for differences between copper/aluminum types by providing stable, long-term termination of aluminium magnet wire - made possible due to 2 IDC slots that provide 4 gas-tight points of contact, 2 on each beam.

Original Press Release:

Tyco Electronics Provides Cost-Effective Termination Solutions for Copper and Aluminum Magnet Conductors

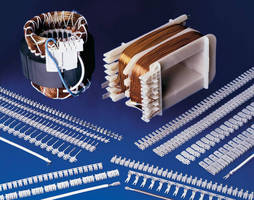

HARRISBURG, PA. - Tyco Electronics offers the MAG-MATE insulation displacement crimp (IDC) interconnection system - a cost-effective interconnect for fractional horsepower (FHP) motor manufacturers. The product drives cost reduction as the same part number qualifies for termination of both copper and aluminium magnet wires.

"Many medium- and high-volume manufacturers of FHP motors for appliance, heating ventilation and air-conditioning (HVAC) equipment are evaluating a switch from copper to aluminium magnet wire to reduce raw material costs," says Fabrizio Longo, Tyco Electronics product manager. "Copper contributes on average about 30 percent to the overall production cost of a FHP electric motor. Switching from copper to aluminium conductors can also reduce transportation costs, as aluminium is about one-third of the weight of copper. Our interconnection system allows manufacturers to easily and cost-effectively bridge the transitions many are making from copper to aluminium magnet wires."

Aluminium conductors have approximately 61 percent of the conductivity and a small fraction of the tensile strength of their copper counterparts. Handling properties also differ as the softer aluminium lacks the resiliency of copper. The MAG-MATE IDC system compensates for these differences by providing a stable, long-term termination of aluminium magnet wire - possible because of two IDC slots that provide four gas-tight points of contact (two on each beam).

In addition, the MAG-MATE system simultaneously terminates two magnet wires of the same size in one terminal. It uses IDC technology to reduce assembly costs by eliminating soldering or stripping. The UL recognized product terminates wire sizes ranging from 34 AWG to 12 AWG for maximum flexibility. Product offerings include multiple lead wire attachment options and special versions that mate with RAST 2.5 IDC connectors.

This product family additionally offers slim-line and mini solutions to meet the needs of customers with space constraints. Specific applications of the product include motor windings, coil and bobbin connections, transformer windings, and lighting ballasts.

For more information on the MAG-MATE IDC interconnection system or to obtain product drawings, visit www.tycoelectronics.com/products/magmatePR .

ABOUT TYCO ELECTRONICS

Tyco Electronics Ltd. is a leading global provider of engineered electronic components, network solutions, specialty products and undersea telecommunication systems, with fiscal 2009 sales of US$10.3 billion to customers in more than 150 countries. We design, manufacture and market products for customers in a broad array of industries including automotive; data communication systems and consumer electronics; telecommunications; aerospace, defense and marine; medical; energy; and lighting. With approximately 7,000 engineers and worldwide manufacturing, sales and customer service capabilities, Tyco Electronics' commitment is our customers' advantage. More information on Tyco Electronics can be found at http://www.tycoelectronics.com/.

MAG-MATE,TE (logo) and Tyco Electronics are trademarks of the Tyco Electronics group of companies and its licensors.