Gear Pumps suit chemical processing industries.

Share:

Press Release Summary:

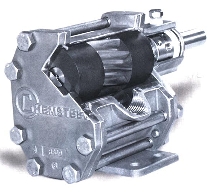

Chemsteel® rotary gear pumps, with flow rates from 1.5 to 30 GPM and duplex capabilities, feature keyed helical gearing for noise reduction. They are available with 15 shaft seal options. Gear combinations include Ryton®, 316 SS Alloy C, Teflon®, and PEEK®. Chemsteel® Pumps can be close-coupled.

Chemsteel® rotary gear pumps, with flow rates from 1.5 to 30 GPM and duplex capabilities, feature keyed helical gearing for noise reduction. They are available with 15 shaft seal options. Gear combinations include Ryton®, 316 SS Alloy C, Teflon®, and PEEK®. Chemsteel® Pumps can be close-coupled.Original Press Release:

Oberdorfer Pumps New Chemsteel(R) Design Available September 2001

The redesign of the Chemsteel® product-line, was officially announced by Oberdorfer Pumps, A Subsidiary of Thomas Industries Inc. The company made the pump available to its distributors and OEM's in September 2001.

Chemsteel,® a rotary gear pump created to meet the demands of the chemical processing industry, with flow rates from 1.5 GPM to 30 GPM, and duplex capabilities, now features keyed helical gearing for noise reduction, wider hydraulic range for both metallic and non-metallic pumps, and 15 shaft seal options. Gear

combinations include Ryton®, 316 SS Alloy C, Teflon®, Ryton® and PEEK®.

Chemsteel® Pumps are available in Rytong, 316 Stainless Steel and Alloy C and can be close-coupled.

Oberdorfer Pumps manufactures pumps for marine, industrial and CPI applications. The pumps are made in aluminum, bronze, cast iron, stainless steel, Alloy C and plastic. Pump varieties include centrifugal, gear pumps, roller pumps, rubber impeller pumps, progressive cavity, and sump types.

Oberdorfer pumps are sold through a worldwide network of industrial and marine distributors. Oberdorfer also specializes in the design and manufacture of custom pumps for OEMs (original equipment manufacturers) who incorporate small pumps into their equipment. The pumps are used for transfer; re-circulation and processing of various chemicals; lubrication oils, water and other fluids.