Gasketing Resin cures on demand.

Press Release Summary:

Used as alternative to tapes, PSA die-cut gaskets, 2K epoxies, silicone rope, or RTV sealants, GA-201 seals heat-sensitive substrates such as plastic enclosures. Moisture- and chemical-resistant FIP/CIP gasket acts as barrier to prevent absorption or penetration of air, dust, dirt, noise, liquids, or gaseous substances. Cured by UV/Visible light, tack-free product can be dispensed into intricate or complex configurations and can accommodate design changes.

Original Press Release:

Increase Production and Cut Costs with New Dymax Gasketing Resin

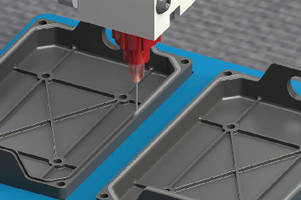

Torrington, Connecticut – Dymax Corporation has introduced GA-201, a UV/Visible light-curable, tack free, moisture- and chemical-resistant FIP/CIP gasket for sealing heat-sensitive substrates such as plastic enclosures. Used as an alternative to tapes, PSA die-cut gaskets, 2K epoxies, silicone rope, or RTV sealants, it helps reduce labor costs and part handling while increasing production throughput. GA-201 can be easily dispensed into intricate and complex configurations and can accommodate design changes without investment in additional tooling. The material cures on demand, eliminating the need for racking and the waste associated with poorly fitting or improperly aligned die-cut gaskets.

GA-201 gasketing material acts as a barrier to prevent absorption or penetration of air, dust, noise, liquids, gaseous substances, or dirt. It provides reliable protection, is easy to use (dispense and cure), cures without damaging heat-sensitive substrates, is cost effective, and reduces process time and part handling.

Dymax Corporation develops innovative oligomer, adhesive, coating, dispensing, and light-curing systems for applications in a wide range of markets. The company’s products are perfectly matched to work seamlessly with each other, providing design engineers with tools to dramatically improve manufacturing efficiency and reduce costs. Major markets include aerospace, appliance, automotive, electronics, industrial, medical device, and metal finishing.

For additional information, visit www.dymax.com or contact Dymax Application Engineering at info@dymax.com or 860-482-1010.