Extrusion Design Tool helps expand production possibilities.

Press Release Summary:

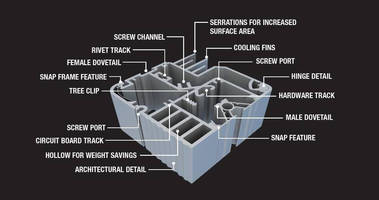

INSPIRE by Almag consists of 3D design tool that guides designers, architects, and manufactures in best way to utilize Extrusion Die technology advancements. To further aid in product design, onsite rapid prototype machine is available. Extrusion Die technology features that can be incorporated into aluminum extrusion include small, hollow cavities; wall thickness < 0 .040 in.; tongue ratios of 9:1 or greater; ability to change between thick and thin walls; and heat sink fin optimization.

Original Press Release:

ALMAG Aluminum Introduces

Ardmore, AL -- ALMAG Aluminum, who designs, extrudes, fabricates, and finishes custom aluminum products for industries around the world, today announced a new extrusion design tool, INSPIRE by Almag, to capitalize on recent advances in Aluminum Extrusion Technology.

The new extruded 3-D design tool is intended to guide designers, architects and manufacturers in the best way to utilize these Extrusion advancements. INSPIRE by Almag can be used as a desk-side reference piece so these key individuals can be reminded of some of the creative potential that aluminum extrusion offers.

To assist with the design and development of new products; ALMAG also offers an onsite rapid prototype machine to bring the customer's design ideas to life.

"One of the biggest benefits of aluminum extrusion is that it can be utilized in any market and that's what makes it exciting," said Rob Nelson, ALMAG Territory Sales Manager.

"ALMAG’s extensive experience in a wide variety of industries from automotive, office furniture, lighting, medical and store fixtures provides tremendous creative potential for our Customers when working on extrusion design," he added.

New advances in Aluminum Extrusion Technology feature many different key features that can be incorporated into aluminum extrusion including:

- Small hollow cavities to allow for optimized weight optimizations

- Wall thickness less than 0.040"

- Tongue ratios of 9:1 or greater

- Faster assembly by incorporating screw ports for quick end cap assembly and T-Slots to fasten opposing products

- Reduced number of parts in an assembly by adding hinges and snap features

- Ability to design in varying wall thicknesses to minimize overall weight while leaving enough material for machining features

- Optimizing heat sink fins to maximize LED cooling with smooth or serrated fins

ABOUT ALMAG ALUMINUM

Since 1953, ALMAG is recognized as an industry leader for producing complex, high-visual, tight tolerance shapes that other extruders won't manufacture. ALMAG Aluminum is a single-source supplier for any aluminum extrusion project, providing design conception and 3-D prototyping for fabricated, and finished parts. ALMAG has won four international design competitions at the Extrusion Technology Conference, as well as the 2012 recognition from the AEC.