Epoxy Coating uses optically active pigment technology.

Share:

Press Release Summary:

Duraplate® UHS (Ultra High Solids) Epoxy, featuring fluorescing Optically Active Pigments (OAP), allows tank lining applicators to check coating instantly for pinholes, holidays, and other discontinuities as well as uniform coverage and film thickness verification. Illuminated under UV-light, product is offered as single- or multi-coat solution and meets requirements of NSF Standard 61 for potable water tanks of at least 1,000 gal. Cure time is 3 days.

Original Press Release:

Sherwin Williams Introduces Coating with Optically Active Pigment Technology

Fluorescing Formula Eliminates Guesswork, Verifies Quality Application Instantly

CLEVELAND, Ohio (April 9, 2007) - Sherwin-Williams Industrial & Marine Coatings now offers its Duraplate® UHS Ultra High Solids Epoxy with fluorescing Optically Active Pigments (OAP), allowing tank lining applicators to check the coating instantly for pinholes, holidays and other discontinuities and verify uniform coverage and proper film thickness.

The new formulation now is the only product of its type meeting the requirements of NSF Standard 61 for potable water tanks of at least 1,000 gallons. The coating uses Duraplate UHS Epoxy as the vehicle to hold the pigment, and is available as a single- or multi-coat application.

A 'civilian' application developed from a proven Sherwin-Williams technology supplied to the U.S. Navy, the fluorescing technology has doubled the service life of marine ballast storage tank coatings simply by illuminating insufficient film thickness wherever it occurs. The result: proper film thickness and uniform coverage can now be verified.

"For a potable water tank, the life expectancy of a two-coat epoxy system, if correctly applied, inspected and maintained, should be more than 40 years," said W. Doni Riddle, Vice President, Sherwin-Williams Industrial & Marine Coatings. "But in the field, owners and engineers have been tolerating early coating failures at 12-15 years of service. When existing specifications are upgraded to require fluorescing pigments, Duraplate UHS OAP can dramatically extend service life."

Traditional holiday detection methods as prescribed by NACE RP-0188 identify bare substrate, but are not designed to pinpoint insufficient film thickness, Riddle said. Nor are these methods practical in areas where wet sponge detection instruments don't fit or can't be set flush to the surface, such as welds, inside angles, supports, stiffeners and piping.

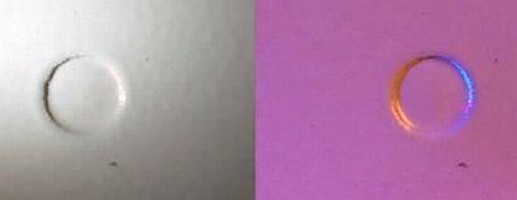

How the system works depends on whether the application is single- or multi-coat. Viewed under ultraviolet light, a single-coat system with Opti-Check OAP pigments will fluoresce or glow even when still wet. Pinholes, holidays and improper film thickness will either appear black in contrast to the fluorescing coating, or not as bright due to insufficient film thickness.

The opposite is true for multi-coat systems. When the primer with OAP is used and the topcoat does not have OAP, pinholes will fluoresce under inspection of the topcoat. Pinholes as small as .25 mils can be identified and corrected before a tank is placed into service using an inexpensive ASTM E 2501-approved light source.

Riddle noted that the coating technology overcomes hurdles that contractor skill can't plan for. "Multiple coat systems are typically specified in contrasting colors to make visual inspection easier," he said, "but even then, holidays can be obscured by glossy coatings and poor lighting."

Combining the OAP's instant holiday detection with the three-day cure time of the Duraplate UHS line gives tanks a better coating application and faster return to service, Riddle said.

Sherwin-Williams Industrial and Marine Coatings group serves North America with a broad line of high-performance coatings, comprehensive technical service and the industry's largest distribution network. Relying on more than 140 years of experience in formulating industrial coatings, the group provides cost-effective solutions for applications where extreme corrosion, abrasion and chemical attack are present.

Direct inquiries to:

MVE Solutions (IMNR606) The Sherwin-Williams Company, c/o Ultimate Lead Systems, P.O. Box 739, Berea, OH 44017, 1-800-524-5979