EDI Polystream Motorized Valve Assembly uses closed loop control system.

Press Release Summary:

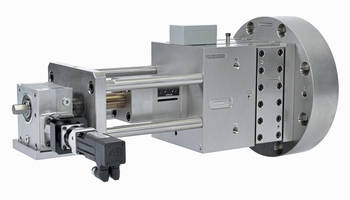

Designed with motor, breaker plate screen pack, linear valve, melt pipe, control system, and optional display panel, EDI Polystream Motorized Valve Assembly provides human machine interfacing. Using closed loop controlling, product is able to maintain back pressure within limit. Designed to provide automatic warning when excess contaminant is build up, motorized valve assembly ensures coat weight consistency and adequate adhesion to substrate.

Original Press Release:

Motorized Valve Assembly for Extrusion Coating Automatically Regulates Back Pressure for Optimal Processing

New PolyStream™ Assembly from Nordson Is a Hands-Free System that Uses Closed-Loop Control to Maintain Back Pressure within a Desired Range for Coating and Laminating

A new patent-pending motorized back pressure valve assembly for extrusion coating and laminating is the first such system to provide closed-loop control, minimizing human error and the possibility of injury when making manual adjustments, it was announced today by Nordson Corporation.

Although extrusion coating operates at higher melt temperatures than other extrusion processes and requires use of a back pressure valve to reach these temperatures, excess back pressure can lead to polymer degradation. Installed between the extruder and the die, the new patent-pending EDI PolyStream™ motorized valve assembly uses closed-loop control to maintain back pressure within a range targeted to ensure optimal processing. The drive for the valve responds to a controller that receives a continuous flow of signals from a pressure transducer, causing the valve to open at varying degrees in accordance with whether back pressure is trending too high or too low. When the valve reaches its limit of opening as a result of excessive contaminant buildup on the filtration screen, an automated warning indicates that it is time to change the screen.

A human / machine interface (HMI) enables the operator to specify process conditions or to use specifications from a recipe. The valve assembly can be run manually, although Nordson recommends automated closed-loop operation.

“The PolyStream valve assembly is the first completely hands-free system for regulating back pressure in extrusion coating,” said Sam G. Iuliano, business development manager for polymer dies. “Back pressure conditions are affected by numerous factors and are in a constant state of flux. By making operator intervention unnecessary, our new system helps to ensure coat weight consistency, adequate adhesion to the substrate, and a high level of product quality.”

The PolyStream assembly includes a motor, breaker plate screen pack, linear valve, melt pipe, control system, and optional display panel.

Nordson Corporation engineers, manufactures and markets differentiated products and systems used for the precision dispensing of adhesives, coatings, sealants, biomaterials, polymers, plastics and other materials, fluid management, test and inspection, UV curing and plasma surface treatment, all supported by application expertise and direct global sales and service. Nordson serves a wide variety of consumer non-durable, durable and technology end markets including packaging, nonwovens, electronics, medical, appliances, energy, transportation, construction, and general product assembly and finishing. Founded in 1954 and headquartered in Westlake, Ohio, the company has operations and support offices in more than 30 countries. Visit Nordson on the web at http://www.nordson.com, @Nordson_Corp.

Nordson Polymer Processing Systems provides customers with engineered components to melt, homogenize, filter, meter, and give shape to plastic and fluid coating materials. Nordson Corporation leverages the collective plastics industry experience from a series of strategic acquisitions to offer a uniquely broad portfolio of industry-leading technologies. Nordson delivers a full range of precision melt stream products — from screws and barrels for extrusion and injection molding — to filtration systems, pumps, and valves — to the extrusion dies and pelletizing systems to meet the constantly evolving needs of the polymer industry.

Nordson Corporation provides customers with local technical sales, service and remanufacturing capabilities through sales organizations and regional manufacturing facilities in over 30 countries. To learn more visit us at http://www.nordsonpolymerprocessing.com.