Dispense System varies flow rate, shot size and mix ratio.

Press Release Summary:

Program-A-Shot 997 dispenses 2-component silicone, epoxy or urethane for potting or encapsulation applications. Flow rate, shot size and ratio can be electronically adjusted to mix and match parts on same production line without reprogramming system. For example, bar-code reader could identify part, then direct system to use programmed profile that dispenses material at pre-determined volume, mix rate and flow rate.

Program-A-Shot 997 dispenses 2-component silicone, epoxy or urethane for potting or encapsulation applications. Flow rate, shot size and ratio can be electronically adjusted to mix and match parts on same production line without reprogramming system. For example, bar-code reader could identify part, then direct system to use programmed profile that dispenses material at pre-determined volume, mix rate and flow rate. Original Press Release:

Program-A-Shot 997 Dispense System Varies Flow Rate, Shot Size And Mix Ration On The Fly

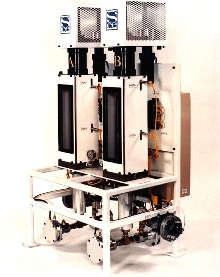

Sealant Equipment & Engineering Inc.'s Program-A-Shot 997 meter/mix/dispense system is ideal for high-volume, automated dispensing of precisely controlled shot sizes of a two-component silicone, epoxy or urethane for potting or encapsulation applications. The system easily and accurately dispenses different-sized shots of reactive materials at variable flow rates and adjustable mix ratios.

All three variables can be electronically adjusted to mix and match parts on the same production line without reprogramming the system. For example, a bar-code reader identifies the part to be processed and directs the 997 system, through a programmed profile, to dispense material at a pre-determined volume and mix rate at a flow rate that can vary during the dispense cycle. Each part receives the exact amount of material at the specified ratio and the required flow rate.