Deburring System is designed for work cell environments.

Press Release Summary:

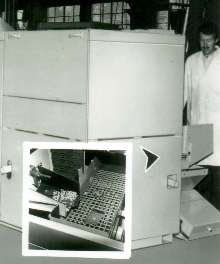

Requiring 92 ft² of floor space, Model V-24TF self-contained, vibratory finishing system features built-in material handling equipment and screener that separates parts from finishing media. It has 24 ft³ capacity, urethane-lined finishing tub and 875-2000 VPM vibration frequency. Sound hoods cover entire length of machine, keeping noise level below 85 dba. Features include user-selectable time cycles, 15 hp variable-speed drive, and spray bar system above tub.

Original Press Release:

Space-Saving Deburring System with Material Handling Designed by Almco for Work Cells

ALBERT LEA, Minnesota (July 8, 2004) -- A compact vibratory finishing system developed by ALMCO, Inc., features built-in material handling equipment and a screener that separates parts from the finishing media while requiring just 92 square feet of floor space.

The self-contained Model V-24TF, from the recognized leader in highly automated and time-saving thru-feed systems, was specifically designed for work cell environments and other tight spaces in all types of industrial operations. It has a 24-cubic-foot-capacity finishing tub and vibration frequency of 875 to 2000 VPM.

Parts along with the finishing media are manually loaded in the ALMCO unit, and a time cycle is selected at a separate electrical pedestal mount. At the end of the finishing process, the machine stops and motor speed is lowered. Parts are manually removed from the screener, while media travels by conveyor back to the loading end and into the tub for re-use.

Sound hoods covering the entire length of the V-24TF are part of the framework. They control noise level below 85 dba to meet OSHA standards.

Another featured component of the system is a 15-hp variable speed drive developed and manufactured by ALMCO. It has fewer parts in the single sliding face, which minimizes the possibility of a break-down and simplifies repairs and parts replacement.

Other features of the V-24TF include a spray bar system above the tub for compound and water entry, and a spray rinse for parts as they enter the screener. The 8-foot tub, measuring 19-3/4 inches wide, is lined with long-wearing urethane, which protects precision parts during the deburring process.

For further information on the Model V-24TF finishing system, contact ALMCO, Inc., 507 West Front Street, Albert Lea, Minnesota 56007, phone 1-800-521-2740, or visit the company on the Internet at www.almcoinc.com. ALMCO is a leading manufacturer of metal finishing, deburring, parts cleaning, and liquid filtration equipment and systems sold through an international network of independent distributors and representatives, and ALMCO region managers.