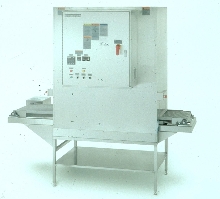

Conveyorized Oven has NEMA-12 enclosure.

Press Release Summary:

CE-compliant Small Conveyorized Curing/Drying Oven features HEPA-filtered, recirculated airflow for operation at Class 100 conditions and better. Corrosion-resistant, stainless-steel conveyor and Teflon®-coated guide rails minimize particulate generation. Oven features variable-speed conveyor and is available with operating temperatures up to 500°F. It handles small, dense loads with 12 lb/linear ft loading capacity on 18 in. wide belt.

CE-compliant Small Conveyorized Curing/Drying Oven features HEPA-filtered, recirculated airflow for operation at Class 100 conditions and better. Corrosion-resistant, stainless-steel conveyor and Teflon®-coated guide rails minimize particulate generation. Oven features variable-speed conveyor and is available with operating temperatures up to 500°F. It handles small, dense loads with 12 lb/linear ft loading capacity on 18 in. wide belt.Original Press Release:

Despatch now offers HEPA Filtration on its Small Conveyorized Oven

Despatch now offers HEPA filtration on its Small Conveyorized Oven

MIANNEAPOLIS - December 17, 2001 - The new Small Conveyorized Curing/Drying Oven from Despatch combines HEPA filtration with a unique conveyor construction, making it ideal for clean process applications in the electronics, medical and other process-critical industries.

Despatch's small conveyorized oven features a HEPA (High Efficiency Particulate Air) filtered, recirculated airflow for operation at Class 100 or better conditions. A corrosion resistant, stainless steel conveyor and Teflon-coated guide rails also help minimize particulate generation during oven operation.

The oven is available with operating temperatures up to 260° C (500° F) and features a variable speed conveyor to accommodate a wide variety of process times. It easily handles small, dense loads with a 12 pound per linear foot loading capacity on an 18-inch wide belt. Customized belt and conveyor sizes can be ordered to meet the user's specific needs.

The oven is CE compliant and has a UL and C-UL listed open control panel with a lockable disconnect switch for easy servicing. All controls and electrical components are housed in an airtight, NEMA-12 enclosure. A removable, side-access panel allows for easy servicing of the fan, heater and HEPA filters, and makes it easy to access the oven interior.