CNC Retrofit Kit fits older boring mills.

Share:

Press Release Summary:

Vega MILM-B Mill PC-based CNC retrofit package helps shops rejuvenate older machines. CNC has handwheel, joystick, and pushbutton jog interfaces, manual tapping, programmable cycles, mirroring and scaling, color LCD display, 32-bit CPU, hard disk, floppy disk and CD ROM. Retrofit package includes on-site installation and operator training. System can interface with both ac and dc servo systems.

Vega MILM-B Mill PC-based CNC retrofit package helps shops rejuvenate older machines. CNC has handwheel, joystick, and pushbutton jog interfaces, manual tapping, programmable cycles, mirroring and scaling, color LCD display, 32-bit CPU, hard disk, floppy disk and CD ROM. Retrofit package includes on-site installation and operator training. System can interface with both ac and dc servo systems.Original Press Release:

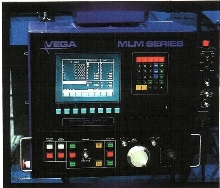

The Vega MLM-B is a Powerful New PC Based CNC for Boring Mills

The Vega MILM-B Mill CNC was specifically designed as a retrofit package for older boring mills. Combining the manual operations that operators love, with the automatic cycles and full 3D CNC programming, this new CNC is just what shops need to rejuvenate their older machines and remain competitive in today's market.

The Vega MLM-B is easy to use and learn, which lowers the learning curve. making operators productive right away. The CNC has a host of features, including handwheel, joystick, and pushbutton jog interfaces, manual tapping, programmable cycles, mirroring, scaling, and many other features that help reduce setup time, improve quality and reduce scrap.

Additional standard features include a color LCD display, 32-bit CPU, hard disk, floppy disk. CD ROM. hand held pendant, full keyboard as well as a user friendly keyboard.

The retrofit package includes on-site installation and operator training, and usually takes 7-15 days. The Vega MLM-B can interface with both AC and DC servo systems, which means that current motors and drives don't have to be replaced. This reduces typical retrofit costs by as much as 40%.