Clean Process Oven is used for production environments.

Press Release Summary:

Stackable LCC1-51 is programmable with microprocessor-based Protocol Plus controller and configured for 220/240 volts and 50/60 Hz. Non-corrosive, 5.1 cu ft stainless steel interior oven chamber handles 200 and 300 mm wafer processing applications. Continuously welded insulation side seams protect work chamber and product from contamination. Recirculated airflow is HEPA filtered, which is monitored for pressure drop by Magnehelic gauge.

Stackable LCC1-51 is programmable with microprocessor-based Protocol Plus controller and configured for 220/240 volts and 50/60 Hz. Non-corrosive, 5.1 cu ft stainless steel interior oven chamber handles 200 and 300 mm wafer processing applications. Continuously welded insulation side seams protect work chamber and product from contamination. Recirculated airflow is HEPA filtered, which is monitored for pressure drop by Magnehelic gauge.Original Press Release:

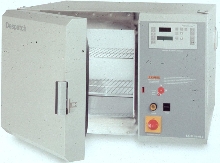

Larger LCC Stackable Clean Process Oven from Despatch Ideal For Production Environments

MINNEAPOLIS - October 8, 2001 - Despatch introduces the LCC1-51, the second in a series of LCC Stackable Clean Process Ovens. The LCC1-51 offers a greater chamber volume and was designed especially for production environments requiring more space for larger parts or bigger loads.

Developed in collaboration with end users in the electronics and semiconductor industries, the LCC ovens redefine the standard for stackable, clean process ovens. "Our first and smaller stackable oven - the LCC1- 16 - was such a success that we created the LCC1-51," said Hans Melgaard, vice president of research and development, Despatch. "Users told us they wanted all of the high-quality, standard features as before with even more chamber capacity. The LCC1-51 delivers all that and more."

Engineered to be stackable

The LCC oven is stackable to save valuable floor space, and all of the serviceable components are easily accessible for maximum efficiency. "With the LCC oven's design, users can get two ovens in the same footprint as one while maintaining ergonomically acceptable loading heights," Melgaard said. "This allows users to double their productivity in the same amount of floor space."

Larger chamber volume

Designed to meet ever-increasing demands in both the electronics and semiconductor industries, the oven's 5.1-cubic-foot chamber is large enough to handle processing applications for both 200 mm and 300 mm wafers, as well as for larger parts and bigger loads.

The chamber also features a non-corrosive stainless steel interior. Continuously welded seams on the insulation side protect the work chamber and product from contamination.

The recirculated airflow is 100 percent HEPA (High Efficiency Particulate Air) filtered for operation at Class 100 or better. A special Magnehelic gauge also monitors the HEPA filter pressure drop so users know when it's time to replace the filter.

SEMI S2 and CE compliance

The oven is SEMI S2 and CE compliant for universal acceptance and is configured for 220/240 volts and 50/60 hz for installations outside the United States. The oven also has a UL and C-UL listed open control panel with a lockable disconnect switch for easy servicing.

Programmable and Networkable

Additionally, the LCC oven features Despatch's programmable, microprocessor-based Protocol Plus controller, designed to make oven operation simple and flexible. Using Despatch's oven networking software, controllers can be networked and connected to a host computer, allowing for centralized operation, monitoring, and data logging of an oven network.

Other standard features

The LCC series of ovens are available in either air or nitrogen atmosphere configurations. Forced exhaust is standard on the air atmosphere units for rapid cool down, and cooling water is standard on the nitrogen units. Also standard is an electric door release and a programmable door lock, which prevents operators from opening the oven door when a cycle is in process. Silicone-free construction also is available for processes sensitive to silicone particulates.