Circular Cold Saws employ various degrees of automation.

Share:

Press Release Summary:

All circular cold saws have positive hydraulic clamping, utilizing 2 self centering infeed vises for precise length control. Cut length is controlled by positive micrometer adjusted, mechanical stop or servo motor. All models are available with low speed spindle for steel or high speed spindle for non-ferrous cutting. Material is clamped on both sides of cut to eliminate hanging burrs. Maximum machine capacity is 4 in. dia round.

All circular cold saws have positive hydraulic clamping, utilizing 2 self centering infeed vises for precise length control. Cut length is controlled by positive micrometer adjusted, mechanical stop or servo motor. All models are available with low speed spindle for steel or high speed spindle for non-ferrous cutting. Material is clamped on both sides of cut to eliminate hanging burrs. Maximum machine capacity is 4 in. dia round.Original Press Release:

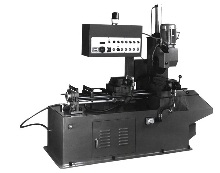

S&S Machinery Corp., Introduces Their Line Of Circular Cold Saws, With Various Degrees Of Automation

All versions employ positive hydraulic clamping, utilizing two self centering, infeed vises assuring precise length control. Cut length is controlled by a positive micrometer adjusted, mechanical stop or servo motor.

The top of the line CNC miter type machine features an Allen Bradley control. All models are available with a low speed spindle for steel or a high speed spindle for non-ferrous cutting. Material is clamped on both sides of the cut eliminating hanging burrs. The coolant systems large capacity tank and a saw blade chip cleaner insures clean cuts and long blade life. Automatic gravity and bundle descrambler type magazine loading systems are available, and when joined to a chamfering &/or endforming machine forms an automated work center.

The machines are of heavy construction. The oil bath gear box features hardened and ground gears, a bronze wheel and heavy duty bearings running in a high quality cast iron housing. Maximum machine capacity to 4" diameter round.