CAM Software enables milling and turning in one application.

Share:

Press Release Summary:

Featuring integrated Mill/Turn module, hyperMILL v9.6 enables complete machining on mill-turn machines in addition to existing 2D, 3D, HSC, and 5-axis strategies. Program can analyze entire component or defined area and recognize all pockets. With active collision avoidance, if shank or holder is set to collide with current stock during roughing, software moves tool path laterally. Complete finishing milling strategy enables machining of flat and steep areas in single operation.

Original Press Release:

New hyperMILL V9.6 with Integrated Mill/Turn Module

hyperMILL® V9.6: Efficient milling and turning in one application

New hyperMILL V9.6 with Integrated Mill/Turn Module: Complete Machining with Maximum Process Reliability

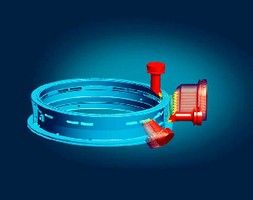

The new Version 9.6 of OPEN MIND Technologies AG's comprehensive hyperMILL® CAM solution now offers even more efficient CNC machining. The integrated hyperMILL® millTURN milling and turning module extends the range of machining strategies so that turning strategies are now also available for complete machining on mill-turn machines in addition to the existing 2D, 3D, HSC and 5-axis strategies. A range of new functions has also been added such as active collision avoidance during roughing, convenient complete finishing and workspace monitoring.

The new version hyperMILL® V9.6 from OPEN MIND Technologies AG is a real highlight for complete machining in a single setup thanks to the new hyperMILL® millTURN module.

Milling and turning with just one program

The advantages of modern mill-turn machines, such as machining in a single setup with a high degree of accuracy and reduced setup times, are used easily and efficiently with this new module. Because the mill-turn module is seamlessly integrated in hyperMILL® V9.6, users can switch between turning and milling strategies at any time while they are programming and they can also generate NC programs very easily. The automatic stock tracking and stock management, the tool database and collision control are available for all turning and milling strategies. A mill/turn postprocessor ensures that a complete NC file is output.

Complete finishing for slope-dependent finishing

The complete finishing milling strategy is optimally suited to machining flat and steep areas in a single operation. All users need to do is specify a slope angle at the point where the machining passes from flat to steep areas. By entering a clearance area for the tool, the smoothest approach and retract strategy is automatically calculated for the approach and retract points. This means users no longer need to choose between different strategies.

Automatic pocket feature recognition

hyperMILL® V9.6 automatically analyzes either the entire component or defined areas and recognizes all the pockets such as open or closed pockets, pockets with and without islands, planar bottom or rounded corners, etc. These can be combined into groups of pockets of the same size, for example, and sorted according to tool position. hyperMILL®'s macro technology can be used to generate automated machining steps.

Active collision avoidance during roughing

hyperMILL® V9.6 provides active collision avoidance thanks to its stock tracking: if the shank or holder is set to collide with the current stock during roughing, hyperMILL® moves the tool path laterally. This allows attaining greater machining depths with current machining job.

Reliable workspace monitoring

hyperMILL®'s machine and material-removal simulation makes it possible to monitor the workspace. A check is made using the stored machine model to see whether the machining job can be completed within the planned machine's workspace or whether limit switches will be traversed. At the same time users can specifically check for potential collisions by looking at the workpiece, holder, setup and machine movements. Potential collisions are displayed in color and the relevant program locations are saved in a list.

Additional information is available on request or from our website at www.openmind-tech.com.

For further information, contact

OPEN MIND Technologies USA, Inc.

Alan Levine

70 Walnut Street

Wellesley Hills MA 02481

Tel.: (781) 239 8095

Fax: (270) 912 5822

Sales.Americas@openmind-tech.com

www openmind-tech.com

About OPEN MIND Technologies AG

OPEN MIND Technologies AG is a leading developer of CAD/CAM software and postprocessors for designing and manufacturing complex moulds and parts. OPEN MIND offers an extensive range of products, from 2D feature-oriented solutions for milling standard parts through to software for 5axis simultaneous machining.

With their hyperMILL® software, which is used in the automotive, tool and mould manufacturing, mechanical engineering and aerospace industries, OPEN MIND Technologies AG is represented in all the important markets in Asia, Europe and North America.

OPEN MIND Technologies AG is a Mensch und Maschine company (www.mum.de).

Head office: OPEN MIND Technologies AG, Argelsrieder Feld 5, 82234 Wessling, Germany

Phone: +49 (0) 81 53 / 93 35 00, Fax: +49 (0) 81 53 / 93 35 01

E-mail: info@openmind-tech.com, website: www.openmind.de

The integrated hyperMILL® millTURN module extends the range of machining strategies so that turning strategies are now also available for complete machining on mill-turn machines.