Belt Sampler provides continuous, real-time sampling.

Press Release Summary:

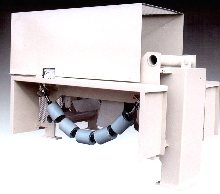

Auto-Belt Sampler(TM) (ABS) automatic system eliminates need for dedicated personnel, and has ability to collect complete cross-sectional aggregate samples from moving conveyor belt in less than 1 sec. Pneumatically operated, unit can be run manually or fully automated. System includes base machine, divider/cutter assembly, contour support idlers at point of sweep, operating sensors, NEMA 12 junction box, and basic hoses and fittings.

Original Press Release:

NEW AUTOMATED BELT SAMPLER PROVIDES CONTINUOUS, REAL-TIME SAMPLING WITH NO NEED TO INTERRUPT PRODUCTION PROCESS

MORRIS, MN - Morris, Minn.-based Superior Industries introduces its new Auto-Belt Sampler(TM) (ABS), an automatic system that provides continuous, real-time sampling information without the need to stop the conveyor belt. The Auto-Belt Sampler eliminates the need for dedicated personnel, and has the ability to collect a complete cross-sectional aggregate sample from a moving conveyor belt in less than one second; a significant improvement over the traditional "stopped-belt" method of sampling. The new system can be easily retrofitted to any point along an existing conveyor, and can be built to accommodate belt widths of almost any size.

Pneumatically operated, the Auto-Belt Sampler can be run manually or fully automated. When combined with an Automated Gradation Unit (AGU), the ABS system will allow the operator to

sweep a sample of crushed aggregate from the moving conveyor belt (at intervals set by the operator), and deposit it through a chute and into the inlet hopper of the AGU for processing.

The new Auto-Belt Sampler system includes a base machine; divider/cutter assembly; contour support idlers at the point of sweep; operating sensors and NEMA 12 junction box; and basic

hoses and fittings for plant air hook-up or complete set up with a self-contained air compressor.

Superior Industries, an Astec company, offers a comprehensive line of components, equipment and systems for the sand, gravel, aggregate, mining, fertilizer, recycling, wood, pulp and paper, chemical processing, electric utility, coal, grain and other processing industries.