Bag Gripper handles up to 50 lb loads.

Press Release Summary:

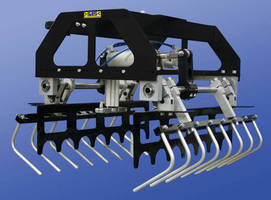

Using stainless steel fingers for their strength and resistance to harsh manufacturing environments, FBG-22 offers manual adjustment for bag widths from 290–450 mm and features spring-return aluminum decking plates to guide bag. Decker mechanism, designed into tool, facilitates accurate bag drop once positioned over pallet, and other design features include rugged aluminum weldment main frame, ultrasonic bag presence sensor, and 9.5 mm dia solid aluminum fingers with ball-nose ends.

Original Press Release:

SAS Automation Introduces FBG-22 Bag Gripper

>SAS< Automation recently introduced a new smaller bag gripper for a variety of bag handling applications including palletizing woven cloth, plastic or paper bags containing heavy products including grains, chemicals, dog food, minerals and plastic resins. This innovative gripper uses stainless steel fingers for both strength and their ability to withstand harsh manufacturing environments. A decker mechanism is designed into the tool to facilitate an accurate bag drop once positioned over the pallet -- crucial for a tightly packed pallet.

Significant Features:

• Lightweight and rugged aluminum weldment main frame

• Manual adjustment for different bag widths from 290-450mm

• Ø9.5mm solid aluminum fingers with ball-nose ends

• Spring-return Aluminum Decking Plates to guide the bag

• Top-mounted Bag Clamp

• High-flow pneumatic solenoid valves

• Ultrasonic bag presence sensor

• Custom adaptor plate to accommodate any robot

• Handles bag weights up to 22kg (50 pounds)

• Weighs 17kg w/o slip sheet option (20kg with)

“This new lightweight bag gripper is a unique tool for palletizing heavy bags,” said Rob Dalton, General Manager for >SAS< Automation. "This gripper is capable of handling bags of multiple weights/sizes,” said Dalton.

About >SAS< Automation

>SAS< is a leading manufacturer and supplier of modular Robotic End-of-Arm Tooling (EOAT), components, and gripper systems, capable of servicing any part and any robot. ISO Certified. Specialists in Robotic End-of-Arm Tooling, custom gripper systems, and automation equipment for automotive, assembly, commercial baking, general material handling, plastics, metal handling, packaging, and palletizing industries.

Sales, service & support to: Asia, Europe, Canada, Mexico, South America, USA.

Company Contact:

Robert Dalton

rdalton@sas-automation.com

SAS Automation, LLC

1200 South Patton Street

Xenia, OH 45385 USA

TEL: +1 937- 372-5255

FAX: +1 937- 372-5555

getagrip@sas-automation.com

www.sas-automation.com

Media Contact:

Barbara Castilano

+1 937-436-2648

bcast@moptions.com

Marketing Options LLC

Marketing Consulting Services

7986 Clyo Rd. Ste B.

Dayton, OH 45459

Tel: 937/436-2648

Cell: 937/654-4614

Fax: 937/436-6156

SKYPE: barb.castilano

Email: bcast@moptions.com

Web: www.moptions.com