AOI Systems support three-dimensional measurement.

Share:

Press Release Summary:

With PILOT 6 inspection software, GOEPEL electronics AOI systems offer possibility of 3D inspection of solder joints on chip components and IC pins. Surface topography data, generated by integrated 3D·EyeZ measuring module, can be evaluated in various ways to determine solder meniscus quality. Pass/fail decision is based on predefined tolerance limits for each parameter of solder joint or component, and additional functionality covers detection of correctness and assembly faults.

Original Press Release:

Three-Dimensional AOI Inspection of Solder Joints of Chip Components and Pins

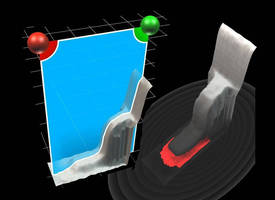

The inspection software PILOT 6 of the AOI systems from GOEPEL electronics offers the possibility of three-dimensional inspection of solder joints on chip components and IC pins with their extended functionality. The data of the surface topography, generated by the integrated measuring module 3D·EyeZ, can be evaluated in many ways to determine the quality of the solder meniscus. Possible functions are the measurement of the soldier height on the component or the pin as well as measuring the tin covered area on the pad and the solder volume.

The pass/fail decision is based on predefined tolerance limits for each parameter of the solder joint or the component. In addition to the 3D solder joint measuring, correctness and assembly faults can be detected. All functions are individually expandable on a modular basis and thereby offer maximum flexibility. The user thereby has access to an extensive library of pre-defined tolerances for all SMD components available.

The 3D functionality is part of the completely new AOI system software PILOT 6. Additional focus of this version is comfortable and fast test program generation with maximum inspection reliability.

Highlight is the integrated SmartGuide, an operating concept for extremely simple test program generation even for unexperienced users. The handling is comparable easy as dealing with a smartphone, thanks to a clear and familiar user interface and touch screen.

About GOEPEL electronic:

GOEPEL electronic is a technologically leading vendor of professional Automated Optical Inspection systems (AOI) and Automated X-ray Inspection Systems (AXI). A network of branch offices in the UK, France, China, India and the USA, international distributors and service partners ensures the global availability of the products as well as the on-site support to several hundred system installations. Founded in 1991 and headquartered in Jena, Germany, GOEPEL electronic has currently more than 200 employees and generated revenue of 25 million Euro in 2013 (approx. $34 million). GOEPEL electronic has continuously been ISO9001 certified since 1996 and has been honoured with TOP-JOB and TOP-100 awards for being one of the best medium-sized companies in Germany. GOEPEL electronics’ industry award winning products are relied on by the leading companies in telecommunication, automotive, space and avionics, industrial controls, medical technology, and other industries. Further information about the company and its products can be found on the internet at www.goepel.com.