Weight Processors offer Profibus-DP communication option.

Press Release Summary:

In addition to EtherNet/IP, Modbus TCP and RTU, and analog 4–20 mA versions, HI 6500 series offers Profibus-DP communications option. HI 6500-PB supports process weighing applications in such industries as food processing, chemical and petrochemical, and general manufacturing automation. Offering stable processed rate with resolution of 1:10:000 and update speed of 110 updates/sec, product can deliver weight readings of up to 4 instruments simultaneously on one display panel.

Original Press Release:

Hardy Process Solutions Adds Profibus-DP to the Communication Options for the HI 6500 Series of Weight Processors

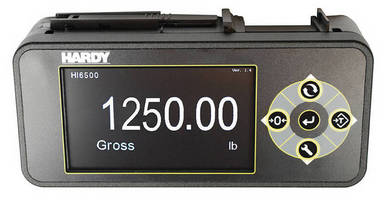

SAN DIEGO---Hardy Process Solutions has announced the release of a Profibus-DP communications option for its field-proven HI 6500 series of weight processors. The Hi 6500 series has a big, bright multi-channel display and delivers fast, high-resolution weight readings. The family includes an EtherNet/IP version as well as Modbus TCP & RTU, and Analog 4-20mA.

Weight processors are used as front ends to control systems or standalone for all types of general industrial weighing applications. Operating blind or with a display, they measure, condition and communicate weight without any need to control. The new HI 6500-PB is designed to support process weighing applications such as inventory management, batch, blending, filling, dispensing, and check weighing.

According to Karl Schwenkmeyer, General Manager, “The new HI 6500-PB series sets the standard for meeting the process weighing needs for a low-cost, fast, high-resolution Profibus-DP weight processor.  The HI 6500 series is designed to meet the application needs of diverse industries, such as food processing, chemical and petrochemical and general manufacturing automation.

Fast, Stable, High Resolution Weight

The HI 6500 series delivers stable processed rate with a resolution of 1:10:000 and an update speed of 110 updates per second (processor, display and communications). The instruments enhance the productivity of process manufacturing systems where fast, precise weight-based controls are critical

With the largest display in the industry for an instrument of this class, the HI 6500 has a 140° viewing angle for viewing up to 100 ft. away. To save cost, space and energy, the HI 6500 series can deliver the weight readings of up to four instruments on one display panel simultaneously. Users can name their display inputs for easy ID and rearrange them in any order.

The HI 6500 series also has the Hardy Process Toolbox, including C2® electronic calibration, INTEGRATED TECHNICIAN® diagnostics, and WAVERSAVER® vibration immunity.

About Hardy Process Solutions

Hardy Process Solutions has established itself as an industry leader in the weighing automation world by providing highly accurate precision measurements, while seamlessly integrating process weight signals into a Rockwell plant control system. In almost all industries, manufacturing operations require materials to be weighed at some point of the production process. Process instrumentation can help improve processes and achieve operational excellence in the four major areas of the supply chain:

1. STOCK - accurate weight and level measurement/monitoring

2. MAKE - adaptable weight & rate material feed measurement/control

3. PACK - for robust rate & weight feed measurement/control

4. SHIP - off-the-shelf static and dynamic check weighing solutions

For further information, visit the Hardy Process Solutions website at www.hardysolutions.com or call Janice Kall at 858-255-6792 or email hardyinfo@hardysolutions.com.