Vibration Welder handles large, thermoplastic parts.

Press Release Summary:

Wide Bed Linear Vibration Welder offers 72 in. wide, 2-speed, variable-force hydraulic lift table and industrial computer with 10.4 in. operator touch panel. Windows(TM)-based software interfaces with Allen-Bradley PLC. System is capable of welding by time, distance, or energy. Weld-graph screen charts wattage, energy, and distance trending. Variable output frequency range is 200-250 Hz and amplitude range is .040-.070 in.

Original Press Release:

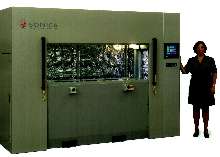

NEW Wide Bed Vibration Welder for Large Thermoplastic Parts

Sonics & Matenrals Inc., Newtown, CT. now offers a wide bed linear vibration welder for welding and bonding large thermoplastic parts. The wide bed machine, which offers a 72" (1829 mm) wide, two speed, variable force hydraulic lift table, incorporates all of the features and benefits of Sonics' standard EH Series vibration welders. These features include an industrial computer with 10.4" (264 mm) operator touch panel and, Windows(TM) based software which is interfaced with an Allen-Bradley PLC. Capable of welding by time, distance or energy, upper and lower limit settings allow the system to weld within a precise process window and, a weld graph screen charts wattage, energy, and distance trending. The system's lower tool weight and travel distance detection promotes ease in set-up and, a modem is provided for remote factory communications. Additional features and benefits include - up to four independent weld pressure, time and amplitude settings, 200 to 250 Hz variable output frequency, .040" (1mm) to .070" (1.8mm) amplitude setting, digitally controlled electromagnetic drive system with four spring head bridge for large upper tool capacity, quick recall job storage, oversized and hinged rear service doors for easy tool access and changeover, safety light curtain, single button touch-and-go cycle start and, Sonics' patented auto-tune function which automatically detects, sets and locks the upper tool's optimum frequency in seconds.

Sonics & Materials, Inc. is a world leader in the field of ultrasonic technology and other plastics joining methods. The company, which is ISO 9001 certified, designs and builds a complete line of hand-held, bench-top, and semi-automated plastics assembly systems, which include microprocessor controlled ultrasonic welders, vibration welders, and spin welders. Sonics offers in-house application assistance, materials testing laboratory service, global sales and distribution network, on-site field service, and the industry's most advanced welding systems. Automotive, industrial, medical, packaging, toy, appliance, consumer, and synthetic textile manufacturers around the world use Sonics' standard or customized equipment to weld the full spectrum of commodity and engineering polymers.

Contact Information:

Sonics & Materials, Incorporated

53 Church Hill Road, Newtown, CT 06470, USA,

Phone: (203) 270-4600, Fax: (203) 270-4610, Toll Free in USA: (800) 745-1105

Email: info@sonics.biz

Web: www.sonics.biz