Treated Lumber suits dry-use applications.

Share:

Press Release Summary:

TimberStrand® laminated strand lumber (LSL) is treated with StrandGuard(TM) process for protection against wood-destroying insects and decay. Zinc-borate used in process is EPA-registered biocide, and is safe for people and environment. Treated sill plates, columns, and studs are straight and true, installing with minimal waste. Product is authorized for applications that fall within American Wood-Preservers' Association Use Categories 1 or 2.

Original Press Release:

Treated TimberStrand® LSL Now Available in Select Markets

BOISE, Idaho (May 6, 2003) Builders have long been seeking an effective alternative for treating wood products - with the new TimberStrand® laminated strand lumber (LSL) treated with the StrandGuard(TM) process, they've found it. Trus Joist's borate-based StrandGuard(TM) patented process for treating wood products provides long-lasting protection against wood-destroying insects and decay.

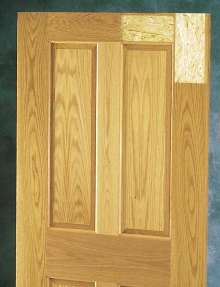

The StrandGuard(TM) process was originally developed and commercialized by Trus Joist in the mid-1990s for use in TimberStrand® LSL door and window components. The zinc-borate used in the StrandGuard(TM) process is an EPA-registered biocide, and has been tested to be safe for people and the environment.

Treated TimberStrand® LSL sill plates, columns, and studs are straight and true, providing fast installation with minimal waste. And, unlike treated solid-sawn lumber, TimberStrand® LSL treated with the StrandGuard(TM) process contains zinc borate throughout its strands, eliminating the need for applying end-cut preservative on the jobsite.

According to Harold Pearman, P.E., of Whetstone Engineering, Inc., "Trus Joist has created a very intelligent process to produce a treated wood product. Treating the material throughout the product further enhances my confidence in its long-term ability to provide protection against termites and decay."

An effective alternative to pressure-treated products within certain applications, treated TimberStrand® LSL is authorized for applications that fall within the American Wood-Preservers' Association (AWPA) Use Categories 1 or 2. TimberStrand® LSL treated framing materials are intended for dry-use applications, but can be used within the building envelope if supported by a masonry or concrete foundation, footing, or slab. Treated TimberStrand® LSL products are not intended for use in ground applications.

Treated TimberStrand® LSL properties are identical to properties for traditional TimberStrand® LSL. The environmental technologies that yield TimberStrand® LSL employ abundant, fast-growing species such as aspen and yellow poplar, which are renewable resources. The TimberStrand® LSL manufacturing process randomizes wood's natural strength-reducing defects, such as knots and pitch pockets, providing consistent, reliable products for specifiers and builders.

Products treated with the StrandGuard(TM) process are currently available in the Western US and will be available in the Eastern US late in the second quarter of 2003. For additional information on TimberStrand® LSL products treated with the StrandGuard(TM) process call 1-800-338-0515, or contact a local Trus Joist technical representative.

Trus Joist, A Weyerhaeuser Business, operates 19 manufacturing plants in North America, a manufacturing plant in Australia and sales offices worldwide. Trus Joist is recognized as the world's leading manufacturer and marketer of engineered lumber products, which provide greater value for the consumer, the builder and the environment.

Trus Joist is a trademark and TimberStrand® and the house and tree logo are registered trademarks of Trus Joist, A Weyerhaeuser Business, Boise, Idaho, USA.