Tool Holder can be programmed to relocate component holders.

Press Release Summary:

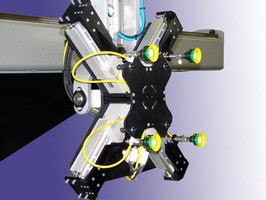

Programmable EOAT tool holder assists molders and manufacturers by eliminating multiple end-of-arm tools and tool changers. Each of 4 tool holders can be used for vacuum cups or grippers mounted on individual linear actuators programmable for up to 28 separate locations. Design allows for interfacing with any robot style or make. Device can be fitted with all standard SAS components.

Original Press Release:

SAS Automation, Introduces Industry First Programmable Robotic End-of-Arm Tooling

Xenia, OH (June 2006) - >SAS< Automation announces an industry first -- Programmable EOAT to assist molders and manufacturers in cost reduction and efficiency. This innovative mechanism can be easily programmed to automatically relocate four separate component holders within the cycle of the robot, all within the same end-of-arm tooling (EOAT).

Each of the four tool holders can be used for vacuum cups or grippers mounted on individual linear actuators which can be programmed for up to 28 separate locations (outputs from binary inputs). Thus, this programmable EOAT can save time and money by eliminating the hassle of dealing with multiple end-of-arm tools and tool changers. Its design allows for easy and fast interfacing with any robot style or make.

With these features incorporated into this programmable EOAT, a robot can pick and place or pull from an injection mold different sized items with just one EOAT. If four separate parts are picked up at one time, the program will also allow for re-positioning of these parts before releasing them. This SAS EOAT can be easily fitted with all of the standard SAS components thus eliminating the cost of custom components.

According to Richard Petz, general manager for SAS "Getting more out of your robot directly relates to having end-of-arm tooling that can handle multi-functions with parts of different shapes and weights. Our new programmable EOAT will allow processors this functionality to help their robot to be more productive."

About >SAS< Automation

>SAS< is a leading supplier of modular EOAT components & robotic gripper systems - capable of servicing any part and any robot. >SAS< manufactures in the USA "get a grip!", and distributes "nip it!" Nile sprue nipper line, and "GRIP IT!" Asian chucking/gripper line. >SAS< is ISO 9001:2000 Quality Certified. Specialists in robotic end-of-arm tooling & gripper systems, sprue nippers, CNC degating & Insert Mold tooling for manufacturing, packaging & plastics industries. Sales, service and support to: USA, Canada, Mexico, Europe.