Thread Grinder employs linear motors on linear ways.

Press Release Summary:

Full helix thread grinder, model GS:TE-LM, allows operators to grind threads, splines, key slots, rings, and other forms on one machine in one setup. It also enables users to optimize dress and grind process by monitoring acoustical emissions. Machine automatically corrects wheel forms for helical path interference or generates forms using standard plated wheels. Product incorporates tenth-micron scale feedback, Fanuc CNC system, and 180° Power Helix.

Original Press Release:

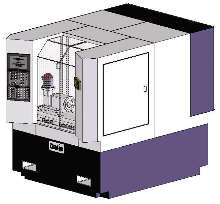

Drake Unveils Linear Motor Thread Grinder at IMTS.

WARREN, OHIO-Unlike the auto industry's concept cars that rarely go into production, Drake Manufacturing has built, sold, and will show off its "concept" thread grinder at IMTS. The GS:TE-LM is a full helix thread grinder equipped with a host of advanced machine design and grinding technologies. Drake wants its customers to be able to grind a wide range of threaded, slotted, or otherwise grooved parts on one machine. The Drake Model GS:TE-LM will enable users to:

· Grind threads, splines, key slots, rings and other forms on one machine in one setup

· Grind using the latest superabrasives with confidence

· Optimize the dress and grind process by monitoring acoustical emissions

· Automatically correct wheel forms for helical path interference or generate forms using standard plated wheels

· Employ machine operators instead of journeymen machinists

· Offer their customers high value added grinding services to remain globally competitive

Drake enables its customers to achieve these ends by equipping its external grinder with:

· Linear motors on linear ways for maximum acceleration and contouring capability with fewer mechanical parts for low maintenance operation

· Tenth-micron scale feedback for world class accuracy now and after years of operation

· Drake Smart Spindle(TM) technology providing automatic balancing, touch dressing, and part feature locating

· Drake Smart Form(TM) technology that automatically generates corrected wheel forms for helical path interference and off helix grinding or calculates setup parameters for generating desired part feature geometry with a standard wheel form

· Full 180° Power Helix

· Mineral filled cast polymer base with excellent thermal stability and vibration dampening

· High static and dynamic stiffness to aggressively grind with the latest super abrasives

· State of the art Fanuc CNC system for reliability

· A lean, clean, ergonomic design and compact footprint for operation in a cell environment

"We wanted to show manufacturers globally what intelligent machine design, coupled with a scientific approach to grinding can do to reduce setup times, improve part quality, and maximize productivity," said John Drake, CEO. "Of course, as a Drake grinder, it will be delivered fully programmed and ready to put our customer's parts out the door from day one."

The GS:TE-LM will be of great interest to customers producing taps, multi-start worms, electronic steering components, fast lead ball screws, feed and bone screws, gear boxes, transmissions and speed reducers," he adds.

Drake Manufacturing designs, builds and services state-of-the-art precision CNC grinding, rack milling and gear hobbing machines that help maximize productivity, improve quality and reduce production costs for a wide variety of demanding applications.