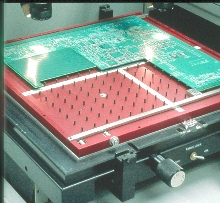

Substrate Support System holds up printed circuit board.

Press Release Summary:

Red-E-Set units provides maximum board support for screen printers producing single and double-sided printed circuit boards. It supports every part of board plus components already placed on board via spring-loaded, non-abrasive support pins that lock into place to fit board's contour. Close spacing of pins allows for maximum support of even densely populated boards.

Red-E-Set units provides maximum board support for screen printers producing single and double-sided printed circuit boards. It supports every part of board plus components already placed on board via spring-loaded, non-abrasive support pins that lock into place to fit board's contour. Close spacing of pins allows for maximum support of even densely populated boards. Original Press Release:

Production Solutions' Red-E-Set(R) PCB Support System Fits MPM's Model SPM Semi-Automatic Stencil Printer Machines

PCB support system adds two hours of machine uptime per day.

POWAY, CA. (September 26, 9001) -Production Solutions Inc., a leading manufacturer of substrate support tooling systems for the electronics assembly industry, offers its Red-E-Set units for use in MIPM's model SPM semi-automatic stencil printing machines. The Red-E-Set support system provides maximum board support for screen printers producing single and double-sided printed circuit boards (PCBs).

The Red-E-Set system's easy configuration greatly reduces setup time. "The development of the Red-E-Set for the model SPM enables users to significantly increase production and throughput by eliminating defective paste deposition due to board flex and by reducing setup time to five minutes or less," says Doug Farlow, Production Solutions President and CEO. "For a manufacturer who produces five different boards in one eight-hour shift, the Red-E-Set can provide up to two additional hours of machine uptime per shift," Farlow continues.

With the Red-E-Set substrate support system, every part of the PCB is supported throughout the screen printing cycle. Unlike similar support systems, the Red-E-Set supports not only the board, but also the components already placed on the board. The system features patented spring-loaded, non-abrasive support pins that lock into place to fit a board's contour for repeat usage. Close spacing of the pins allows for maximum support of even the most densely populated boards.

"A typical shop using an SPM screen printer with four to five setups per day can expect a return on investment (ROI) in as little as four months due to the increased machine uptime that results from the use of the Red-E-Set," says Farlow. "The traditional tooling system offered cannot provide adequate support for today's densely populated, double-sided boards and can take as much as 30-45 minutes per set-up. When you combine this with the improved quality performance of the Red-E-Set, the increased throughput and cost savings are significant," Farlow concluded.

Red-E-Set units are available from stock to four weeks. The Red-E-Set substrate support system comes with a 30-day satisfaction guarantee. Production Solutions also offers a Red-E-Set In-Line model that is compatible with all automatic screen printers, dispensing systems and automated assembly equipment and is less than half the price of competitors' systems. Pricing for the Red-E-Set Family ranges from $750-$3,500.

Substrate support systems

Production Solutions Inc. is a manufacturer of substrate support tooling systems for the electronics industry. Headquartered in Poway, California, Production Solutions Inc. manufactures and distributes a patented substrate support system for printed circuit board screen printers, dispensing systems and automated assembly equipment.