Strip Shaft allows smooth winding of web materials.

Press Release Summary:

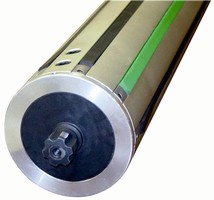

Featuring wear-resistant gripping elements and polyethylene centering strips, SRS-2000 self-centering strip shaft creates and maintains consistent axis of rotation for roll. Centering strips support roll as bladders compress during rotation, minimizing roll bounce, and independent bladder control system. Available in 3 and 6 in. diameters, shaft utilizes air activation system with no moving parts.

Original Press Release:

Self-Centering Strip Shafts

Double E has expanded its "SR" series of products to include the SRS-2000 self-centering strip shaft. The shaft creates and maintains a consistent axis of rotation for the roll, allowing smooth winding of sensitive web materials. It features a unique combination of wear-resistant gripping elements and polyethylene centering strips. The centering strips help to support the roll as the bladders compress naturally during rotation, minimizing the roll bounce that can occur with standard strip shafts. The SRS-2000 is an ideal solution for film applications with a nip roll present because the roll bounce phenomenon often allows wrinkling to occur when pressure is being applied. The self-centering shaft yields consistent pressure from the nip roll all the way around the winding roll. This consistent pressure minimizes web damage.

The shaft comes standard in 3-inch and 6-inch diameters, but it also can be custom ordered to fit other core sizes. It also features Double E's independent bladder control system. This system ensures roll security and safe operation even if one bladder fails. Replacing a bladder is a simple operation that can be performed without removing the shaft from the machine. The SRS-2000 utilizes a newly designed air activation system, which has no moving parts and is virtually maintenance free. Double E Company, 319 Manley Street, West Bridgewater, MA 02379. Tel: (508) 588-8099;

Fax: (508) 580-2915; email: doublee@doubleeusa.com; website: www.doubleeusa.com.