Straightener/Feeder features computer control.

Press Release Summary:

LCC-HF2 Straightener/Feeder, equipped with HM-type Computer Control System (CCS), handles metals from 1.97 in. to 39.37 in. wide and up to 0.18 in. thick. It accepts maximum coil weights up to 10 tons and maximum coil O.D.s of 60 in. Features include no-loop detector, photo sensor loop control, pilot roll, handwheel adjustment, end-of-stock detector, and pneumatic or hydraulic expansion systems.

LCC-HF2 Straightener/Feeder, equipped with HM-type Computer Control System (CCS), handles metals from 1.97 in. to 39.37 in. wide and up to 0.18 in. thick. It accepts maximum coil weights up to 10 tons and maximum coil O.D.s of 60 in. Features include no-loop detector, photo sensor loop control, pilot roll, handwheel adjustment, end-of-stock detector, and pneumatic or hydraulic expansion systems.Original Press Release:

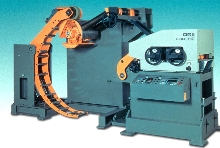

ORRIMEC's High Performance LCC-HF2 Straightener/Feeder With New HM-Type CCS Offers Simple, Superior Operation

ORTIMEC'S HIGH PERFORMANCE LCC-HF2 STRAIGHTENER/FEEDER

WITH NEW HM-TYPE CCS OFFERS SIMPLE, SUPERIOR OPERATION

ERLANGER, KY (October 23, 2001) - The high performance and superior operation of the ORIIMEC LCC-HF2 Straightener/Feeder, equipped with the new HM-Type CCS (Computer Control System), places it at the pinnacle of the HF series.

The LCC-HF2 handles a wide range of metal from 1.97" (50 mm) to 39.37" (1,000 mm) wide and up to 0.18" (4.5 mm) thick, with a maximum coil weight of 10 tons and a maximum coil outside diameter of 60" (1,524 mm). Larger sizes are available upon request.

Standard features include a no-loop detector, photo sensor loop control, pilot roll, handwheel adjustment for stock guides, end-of-stock detector, driven coil-hold-down roll, roll-type coil side guides, threading table, remote pendant and pneumatic or hydraulic expansion systems.

Common options available for the LCC-HF2 are press feed master control, programmable punch gaging, zig-zag feed, digital cam switch, hard chrome plated roll, stock lube system, ORII-TRON, coil car, feed angle select switch and an alligator head for easy roll cleaning.

The eight models and 26 variations of the ORIIMEC LCC series of straightener/feeder systems offer features and capacities to meet every press stamping need, from space-saving systems to heavy-duty systems.