Software automates machining operations.

Share:

Press Release Summary:

Run from dedicated PC, Cell Master v5.0 real-time Cell Management System prepares, organizes, and executes work in automated CNC machine environment for toolmaking, moldmaking, and job shop machining. Windows-based program controls robot, machine tools, and scheduling, enabling jobs to be rearranged, added, or deleted without interrupting machine tools. System supports all types of machining and allows use of multi-Axis robots or lading devices in single or multiple machine cell.

Original Press Release:

Hirschmann Cell Master 5.0 Now Available

HIRSCHMANN Engineering U.S.A., Inc., Buffalo Grove, Illinois, announces the availability of its real-time Cell Management System (CMS) for preparing, organizing and executing work in an automated CNC machine environment for toolmaking, moldmaking and job shop machining. The CMS Software is a Windows based PC program that controls the robot and machine tools in an automated CNC machining cell.

CMS supports all types of machining including: Milling and HSM machining, Wire EDM, Sinking EDM, and other specialty machining applications. With CMS in charge, the following tasks can be handled without stopping any of the machine tools in the cell:

· Jobs can be reorganized by changing their machining order or be put on hold.

· Pallets containing new work can be added to the cell.

· Finished work can be removed from the cell so that the tooling can be reused for new projects.

· Real-time cell status data can be obtained at any time.

In the tool room or job shop workpieces are loaded in and out of a machine in the proper sequence so that they are machined with the proper NC programs. The NC Control can perform this balancing act through the use of Macros and "M" functions coordinating the machining process. However, the NC Control was not designed to function as a shop foreman as job schedules change. A dedicated PC running HIRSCHMANN's Cell Master software controls the scheduling of jobs in the cell. This way jobs can be rearranged, added or deleted at the click of a button without interrupting the machine tools in the cell.

HIRSCHMANN's new "Cell Master Software" was developed to meet these needs. The software can be connected to any machine tool that meets minimum requirements. It allows the use of multi-Axis robots or lading devices in a single or multiple machine cell and directly integrates with the Hirschmann Presetter Program for job preparation. Individual jobs are scheduled, added or deleted with a click of a mouse, taking advantage of the automation capabilities of the machine tool control.

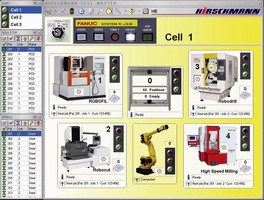

The software is the "Master" of both the machine tools and the robot. Jobs are prepared with the Hirschmann "Presetter" program where workpieces are mounted to the pallet and linked to the NC Programs. Data is transferred to the Cell Master database to allow the jobs to be entered into the job "Queue". When a job is placed into the queue, its machining order can be changed; it can be placed on hold if production needs to be stopped temporarily; or it can be deleted from the queue. The product uses a graphical overview of the cell to show the current status of all jobs in the cell and the current location of all the pallets in the shop.

For additional information about Cell Master 5.0 software contact sales at:

HIRSCHMANN Engineering USA, Inc.

1558 Barclay Blvd.

Buffalo Grove, IL 60089

Phone: 847-419-9890

Fax: 847-419-9895

Web Site: www.hirschmannusa.com

E-Mail: info@hirschmannusa.com

Incorporated in 1992, Hirschmann Engineering, USA, Inc. is a subsidiary of Hirschmann GmbH, Germany, a privately owned ISO 9001 certified company founded in 1957. Hirschmann Engineering USA, Inc. is the sole importer of all products manufactured by the parent company and by Oelheld GmbH, a producer of synthetic metalworking fluids. Oelheld is an ISO 9001 certified company, founded in 1887. Hirschmann Engineering USA, Inc. is responsible for sales, service, and technical support for all of North America.